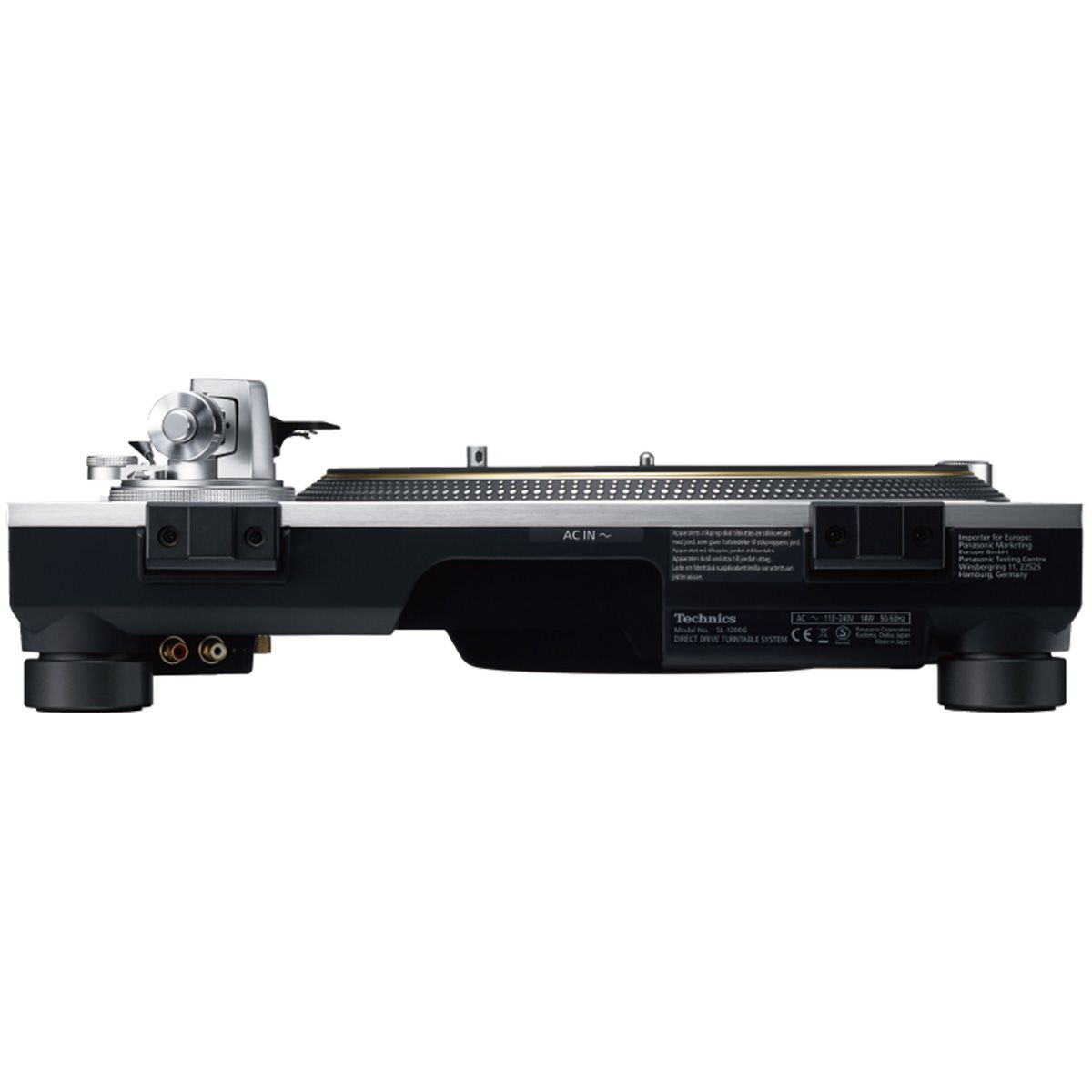

| Content | Turntable section

Type: Direct Drive Manual Turntable

Turntable Speeds: 33 1/3, 45, 78 rpm

Adjust Range: ±8%, ±16%

Starting Torque: 3.3 kg・cm (2.8 lb-in)

Build-up Characteristics: 0.7 s. from standstill to 33 1/3 r/min

Wow And Flutter: 0.025% W.R.M.S. (JIS C5521)

Rumble: 78dB (IEC 98A Weighted)

Turntable Platter:

- Brass and Aluminum diecast combined

- Diameter:332mm (13-5/64")

- Weight:About 3.6kg (7 15/16 lb) (Including rubber sheet)

Tonearm Section

Type: Universal Static Balance

Effective Length: 230mm (9-1/16")

Overhang: 15mm (19/32")

Tracking Error Angle:

- Within 2° 32' (at the outer groove of 30cm(12") record)

- Within 0° 32' (at the inner groove of 30cm(12") record)

Offset Angle: 22°

Arm-height Adjustment Range: 0 - 6 mm

Stylus Pressure Adjustment Range: 0 - 4 g (direct reading)

Terminals

Audio Output PHONO (Pin Jack) x 1

EARTH TERMINAL x 1 | The C-Sharp packs one heck of a lot of technology into its price tag. First of all, the package price includes the $1000 Ortofon Quintet Black cartridge, praised by audiophiles all over the world for its natural sound. The heavy platter with a ceramic bearing, 10" carbon tonearm, and external speed control unit give you an amazing combination. EAT's special damping technology will keep both external noise and motor noise away from your records. Plus it will look like a true work of art sitting on your audio rack with its striking European styling. Just do some stretching before you set it up because this jewel weighs in at 30 pounds!

Design & Build Quality

When we first looked at the EAT turntables, two things really impressed us -- the great looking design and the superb build quality. They just exude European precision. Like many of our favorite turntables, the C-Sharp is a fully manual turntable. This means to operate it you’ll turn it on, manually lower the tonearm using the damped cueing lever, then at the end of your record, use the cueing lever again to raise the arm. At Audio Advice we prefer manual tables for their simplicity. There’s an argument to be made that the lack of mechanical parts also prevents issues such as resonance from affecting the tables great sound.

The look of the C-Sharp is quite stunning. Unlike many high-end turntables, the C-Sharp is elegant and relatively low-profile. The carbon fiber plinth sits in a high-gloss black base with a thin edge. The platter is much larger than a 12” record and tapers up to the high tech mat. A substantial record clamp is included in the box. The tonearm is also a work of art, constructed from carbon fiber and highly-polished aluminum components. The whole thing looks like something you would expect to find under the hood of a $1m race car!

As soon as you begin to interact with the C-Sharp it quickly becomes clear that build quality it is second to none. This is to be expected for it’s nearly $3,500 price point, but it’s just an incredibly well put together table.

Features & Technology

The low profile base of the C-Sharp is made out of the highest density MDF available. The ultra-low-noise motor is mounted to the base along with 10 cone-shaped damping feet made out of a new high tech energy absorbing material called TPE (Thermoplastic Elastomer). The plinth constructed from a sandwich design of carbon fiber over MDF. The base has three adjustable feet, which allow you to get things perfectly leveled.

The main platter bearing sits on the carbon fiber plinth which is supported by the TPE columns. This makes for a great isolation system. If you gently push down on the plinth, you can even feel the spring of these columns. The combination of these features limits the amount of noise able to get back into the system, maximizing the sound quality.

The turntable bearing is one of the most unique designs we have seen. It is an oversized inverted design with a resonance-free ceramic ball bearing on top. The larger inner platter has a massive brass bearing which sits on top of the ball bearing and also extends above the inner platter to provide a perfect fit for the substantial outer platter. Everything fits together with incredible precision! Any vibration noise that does make its wait though is just transferred out to the TPE columns. Quite a brilliant design.

The main outer platter is very heavy, coming in just an ounce shy of 11 pounds! When you flip it over, see why they made it larger than an LP. The outer perimeter is a weighted ring to give it a flywheel effect. The main platter itself is another sandwich-type design, this time with a very inert aluminum sandwiching some more TPE material. The part of the platter that contacts the record is constructed from recycled records! Topping the platter is a threaded spindle for the included heavy-duty machined record clamp.

To be honest, it’s a little scary during the setup process, trying to center an 11-pound platter on the inner platter. It’s a precision fit, so you’ve got to get it line up just right. Be careful not to mash your fingers as you lower it. The good news is that it fits perfectly and you should really only have to do this the first time you set it up. We recommend you attach the clamp, screw it on firmly, and then gently lower it down while holding it by the clamp.

Even the belt is a bit exotic. It’s constructed from a special antistatic rub, is round like many ultra-high-end turntable belts, and is polished for uniformity.

Like the rest of the turntable, the tonearm also has a ton of great technology buried inside of it. It’s a combination of a unipivot tonearm and traditional pivot design with the middle bearing being a unipivot. When you move it around, you can’t feel any play at all, which is something we look for. It also is virtually friction-free. The arm tube is made of carbon filled with a special silicone grease to damp out any resonances. This arm can fully support just about any type of high-end cartridge you would want to use, which our customers love.

The tonearm has fully adjustable vertical tracking height. You’ll need a stylus pressure gauge to set the tracking force as it is all gravity and there are no markings on the counterweight. Fortunately, a very nice one is included with the table. The anti-skating is a very clever gravity design as well, but you’ll need some pretty good eyesight to get it all set up properly. It has to screw into the side of the tonearm base, then wrap around. Once it's set up, there is no risk of it getting changed, like some gravity designs, but is just a little trickier to start with. Of course, if you purchase your C-Sharp from Audio Advice, we will do all of this for you.

The external power supply is fully isolated and easily allows you to switch between 33 and 45. It has an AC generator built in for totally clean and stable power to the motor.

Finally, the package we are testing comes fitted with an Ortofon Quintet Black. When you consider the C-Sharp without a cartridge is $2,995 and with the $1,000 Quintet Black, it's $3,495, you get a $500 savings buying the package -- an incredible value.

Performance

We had recently set up a nice system to run our new Golden Ear Triton Reference using a PrimaLuna Dialogue integrated amp and the Sutherland Duo phono stage. We decided that this would be a fun rig to use to test out the EAT C-Sharp. First off, that combo sounds just amazing! The Tritons have a powered sub built in and the Prima Luna had no trouble driving them. The system provided an incredibly warm, rich sound -- just as we would expect.

We set up the Sutherland for 100 ohms and set the gain to 60db and started spinning some vinyl. The first thing we noticed was the great deep bass extension. We had on a Norah Jones record with some acoustic bass. Not only was it deep and full, but you could hear all of the harmonics of the instruments. The way her voice floated dead center with such a great sense of effortlessness.

Dynamics were also outstanding, especially on an old Judds album, Why Not Me. This one was really fun to listen to. Changing over to some Miles Davis Kind of Blue was just stunning. Every instrument stood out in a huge soundstage, yet each one was the right size and precisely located, never wavering. We finally cued up one of our favorite LP’s for rhythm and pacing, John Cougar’s “Pink Houses” cut from his Uh-Huh album. The C-Sharp passed this test with flying colors as we had our feet tapping within the first few bars!

Using the C-Sharp is a great experience as well. You drop the weight on the center spindle and give the center portion a spin to lock it in. Push 33 or 45 on the speed control box, wait until the light stops flashing to indicate things are up to speed and then lower the tonearm. The Quintet makes cueing up songs very easy as its square body makes it easy to line up the groove you want to land in.

We just loved using the C-Sharp! |

The MMF-5.3 turntable is a 2-speed belt driven audiophile turntable employing the unique dual-plinth construction originated by Music Hall.

- Counterweight's center of gravity is level with the stylus tip, is decoupled from the arm, and acts as a resonance damper.

- DC synchronous motor for superior speed stability separately isolated on the lower platform.

- Includes properly aligned and pre-mounted Ortofon 2M Blue cartridge with a replaceable nude elliptical diamond stylus.

- Dynamically balanced alloy platter with soft felt mat.

- Dust cover and 45 rpm adaptor included.

| The Planar 10 features the new RB3000 tonearm fitted with an improved, low mass, precision bias housing. Rega has pioneered a completely new low mass, central hub bearing assembly with improved mechanical integrity. For the first time on a Rega production turntable, a ceramic top brace delivers ultimate rigidity and accuracy whilst creating the perfect platform between tonearm and central bearing. Finally, this entirely new player is controlled by their most advanced electronic power supply housed in a brand-new, full metal custom case designed to match the latest range of Rega electronics.

.jpg) Ultra-lightweight plinth

The Planar 10 is the third Rega turntable constructed using their latest technology the ultra-lightweight Tancast 8 polyurethane foam core (a material developed for the aerospace industry). This material is sandwiched between two layers of HPL (high-pressure laminate). HPL is exceptionally thin and extremely rigid. This new construction makes the new Planar 10 skeletal plinth 30% lighter than the original RP10 while offering increased rigidity over the previous model.

DB Technology (Double Brace Technology)

A super lightweight plinth combined with a ceramic top brace and phenolic resin bottom brace mounted specifically where the increased rigidity is required (between the tonearm mounting and the main hub bearing) forms a structurally sound, “stressed beam,” assembly. This rigid plinth design prevents energy absorption and unwanted resonances which will add unnatural distortions to the music. Equally, heavier mass can transfer more unwanted energy such as motor or bearing noise directly into the rotating record. The tonearm and cartridge must be able to read accurately, directly from the platter. This unique Rega double brace solution enables this. The use of braces instead of the complete skin allows increased thickness in these key areas while providing further weight reduction to the plinth which directly addresses the issue of mass absorption and unwanted energy transmission.

RB3000 tonearm

Rega is renowned for the quality of its tonearm bearing assemblies. In particular the accurate manufacturing of their bearing housing and bearing spindles. Technical characteristics such as "roundness" and "parallelity" are critical. Over the past three years, Rega has found a new manufacturing process that improves on all these characteristics resulting in a micron perfect bearing fit. The RB3000 is the first Rega arm to benefit from these improvements.

The entire tonearm structure is designed to have the minimum of mechanical joints while using the stiffest materials in all critical areas. The tolerance of the RB3000 tonearm is so tight that no adhesive is used at any point throughout the construction. Their latest low mass, precision-engineered, the vertical bearing assembly has been manufactured to further complement the inherent design philosophy of the Planar 10 turntable. The RB3000 tonearm uses Rega's advanced, preloaded zero tolerance bearing assembly adjusted to less than 1000th of a mm. This gives friction-free movement and zero levels of unwanted play. Simply put, friction-free bearings with no play enable ridges in the record groove of less than a micron to be read. The RB3000 also uses their latest award-winning, aluminum, Rega arm tube (each one of which is meticulously hand polished, keeping mass to an absolute minimum) which was redesigned to redistribute mass and further reduce stresses and resonances. This advanced design tube increases the stiffness and rigidity of the overall assembly whilst reducing stress on the bearings even further.

Hub Bearing assembly

The Planar 10 uses a new low mass central bearing assembly. A single piece of machined aluminum sub-platter and hardened tool steel spindle run inside a custom brass housing designed with improved mechanical integrity. The complete assembly is cleverly mounted within the chassis to eradicate unwanted potential energy being transferred or stored in the plinth.

Ultra-lightweight plinth

The Planar 10 is the third Rega turntable constructed using their latest technology the ultra-lightweight Tancast 8 polyurethane foam core (a material developed for the aerospace industry). This material is sandwiched between two layers of HPL (high-pressure laminate). HPL is exceptionally thin and extremely rigid. This new construction makes the new Planar 10 skeletal plinth 30% lighter than the original RP10 while offering increased rigidity over the previous model.

DB Technology (Double Brace Technology)

A super lightweight plinth combined with a ceramic top brace and phenolic resin bottom brace mounted specifically where the increased rigidity is required (between the tonearm mounting and the main hub bearing) forms a structurally sound, “stressed beam,” assembly. This rigid plinth design prevents energy absorption and unwanted resonances which will add unnatural distortions to the music. Equally, heavier mass can transfer more unwanted energy such as motor or bearing noise directly into the rotating record. The tonearm and cartridge must be able to read accurately, directly from the platter. This unique Rega double brace solution enables this. The use of braces instead of the complete skin allows increased thickness in these key areas while providing further weight reduction to the plinth which directly addresses the issue of mass absorption and unwanted energy transmission.

RB3000 tonearm

Rega is renowned for the quality of its tonearm bearing assemblies. In particular the accurate manufacturing of their bearing housing and bearing spindles. Technical characteristics such as "roundness" and "parallelity" are critical. Over the past three years, Rega has found a new manufacturing process that improves on all these characteristics resulting in a micron perfect bearing fit. The RB3000 is the first Rega arm to benefit from these improvements.

The entire tonearm structure is designed to have the minimum of mechanical joints while using the stiffest materials in all critical areas. The tolerance of the RB3000 tonearm is so tight that no adhesive is used at any point throughout the construction. Their latest low mass, precision-engineered, the vertical bearing assembly has been manufactured to further complement the inherent design philosophy of the Planar 10 turntable. The RB3000 tonearm uses Rega's advanced, preloaded zero tolerance bearing assembly adjusted to less than 1000th of a mm. This gives friction-free movement and zero levels of unwanted play. Simply put, friction-free bearings with no play enable ridges in the record groove of less than a micron to be read. The RB3000 also uses their latest award-winning, aluminum, Rega arm tube (each one of which is meticulously hand polished, keeping mass to an absolute minimum) which was redesigned to redistribute mass and further reduce stresses and resonances. This advanced design tube increases the stiffness and rigidity of the overall assembly whilst reducing stress on the bearings even further.

Hub Bearing assembly

The Planar 10 uses a new low mass central bearing assembly. A single piece of machined aluminum sub-platter and hardened tool steel spindle run inside a custom brass housing designed with improved mechanical integrity. The complete assembly is cleverly mounted within the chassis to eradicate unwanted potential energy being transferred or stored in the plinth.

Cutaway cross-section of Planar 10 bearing assembly.

Ceramic Platter

The P10 uses a custom ceramic, flywheel effect platter. The platter is produced from ceramic oxide powder which is compressed, fired and diamond cut to ensure perfect accuracy and flatness across the surface. The latest platter features a modified construction with improved coupling to the sub-platter.

24v Low noise motor assembly

The Planar 10 uses Rega's latest generation, 24v, synchronous, low vibration motor technology. Uniquely mounted using the highest level of coupling while retaining higher vibration isolation than any previous model, this new motor mounting technique (mounted from the bottom) has been taken directly from the ultimate Rega turntable, the Naiad. This unique mounting method removes all stress from the motor body whilst holding the drive pulley perfectly still. This enables better speed stability and accuracy from the turntable. The reduced vibration and more rigid mounting delivers superior drive from the new EBLT drive belts. Each motor is hand-tuned to match its own custom-matched PL10 PSU power supply before fitting to the turntable to optimize the anti-vibration circuit.

EBLT Drive Belts

For three years Rega has been researching and developing with chemists the use of a bespoke new rubber compound for drive belts. Using a specialized curing system, the new drive belt offers superior consistency of modulus (a constant representing the degree to which a substance has a particular property, especially elasticity). These new belts are manufactured on Rega designed, state of the art, super-accurate tools (inspired by working with the manufacturer of high-tech Formula 1 engine parts) which produce 'perfectly round' and 'dimensionally accurate' belts, critical for perfect speed stability.

PL10 PSU custom-matched advanced power supply.

The PL10 PSU offers the ultimate in motor control stability, convenient electronic speed change, advanced anti-vibration control, and user-adjustable electronic fine speed adjustment to ensure total accuracy and control over the life of the motor. Housed in Rega's latest custom-designed case, the PL10 PSU is dedicated to running our 24v, low noise motor as quietly and as accurately as possible. The speed and control of the motor is achieved by using a new DSP (Digital Signal Processing) generator built upon a high stability crystal. This device will divide the accurate square wave from the crystal to the exact frequency required to turn the platter at the selected speed. The DSP core will also generate a near perfect sinusoidal waveform to power the motor. Factory set vibration removal and fine speed adjustments are then made to the power supply to tune each motor for optimal performance.

Dust Cover

The outer frame of the previous model has now been removed and a new stylish, removable, single piece dustcover has been introduced further reducing the overall mass of the turntable.

Cutaway cross-section of Planar 10 bearing assembly.

Ceramic Platter

The P10 uses a custom ceramic, flywheel effect platter. The platter is produced from ceramic oxide powder which is compressed, fired and diamond cut to ensure perfect accuracy and flatness across the surface. The latest platter features a modified construction with improved coupling to the sub-platter.

24v Low noise motor assembly

The Planar 10 uses Rega's latest generation, 24v, synchronous, low vibration motor technology. Uniquely mounted using the highest level of coupling while retaining higher vibration isolation than any previous model, this new motor mounting technique (mounted from the bottom) has been taken directly from the ultimate Rega turntable, the Naiad. This unique mounting method removes all stress from the motor body whilst holding the drive pulley perfectly still. This enables better speed stability and accuracy from the turntable. The reduced vibration and more rigid mounting delivers superior drive from the new EBLT drive belts. Each motor is hand-tuned to match its own custom-matched PL10 PSU power supply before fitting to the turntable to optimize the anti-vibration circuit.

EBLT Drive Belts

For three years Rega has been researching and developing with chemists the use of a bespoke new rubber compound for drive belts. Using a specialized curing system, the new drive belt offers superior consistency of modulus (a constant representing the degree to which a substance has a particular property, especially elasticity). These new belts are manufactured on Rega designed, state of the art, super-accurate tools (inspired by working with the manufacturer of high-tech Formula 1 engine parts) which produce 'perfectly round' and 'dimensionally accurate' belts, critical for perfect speed stability.

PL10 PSU custom-matched advanced power supply.

The PL10 PSU offers the ultimate in motor control stability, convenient electronic speed change, advanced anti-vibration control, and user-adjustable electronic fine speed adjustment to ensure total accuracy and control over the life of the motor. Housed in Rega's latest custom-designed case, the PL10 PSU is dedicated to running our 24v, low noise motor as quietly and as accurately as possible. The speed and control of the motor is achieved by using a new DSP (Digital Signal Processing) generator built upon a high stability crystal. This device will divide the accurate square wave from the crystal to the exact frequency required to turn the platter at the selected speed. The DSP core will also generate a near perfect sinusoidal waveform to power the motor. Factory set vibration removal and fine speed adjustments are then made to the power supply to tune each motor for optimal performance.

Dust Cover

The outer frame of the previous model has now been removed and a new stylish, removable, single piece dustcover has been introduced further reducing the overall mass of the turntable.

- Mains voltage:

- 230 V 50/60 Hz

- 220 V 50/60Hz

- 115 V 50/60Hz

- 100 V 50/60Hz

- Power consumption: 17 W

- Fuse rating: T250 mA L (230 V / 220 V)T500 mA L (115 V / 100 V)

- Output to motor: 24 V AC bi-phase ~ 350 mA

- Speed control step size: 0.01 rpm

| Thanks to extensive research and development, we have now elevated our classic RPM design to an even higher level. The RPM 10 Carbon uses a new extra-heavy chassis which features a special CNC-machined MDF base with resin-coated steel pellets to form an extra-heavy and precise sandwich construction. A special, complex heat treatment and carbon surface coating ensures superior low resonance levels. The mass-loaded chassis is effectively decoupled from its surface using magnetic feet. Combined with a new special polished aluminum platter with internal TPE damping and a vinyl layer on top, the inverted ceramic main bearing delivers an absolutely stable turntable speed with extra-low rumble due to the magnetic suspension of the platter. The heavy outboard motor unit is equipped with precise motor control and features a built-in switch between 33 & 45 rpm. Last but not least, the no-compromise 10" EVO tonearm with conical carbon-fiber arm tube and inverted bearing design ensures perfect tracking, even with demanding cartridges. Highly flexible, top-grade copper internal wiring is used. The RPM 10 Carbon is delivered with Ground it Carbon equipment base and top-grade 5P phono cable "Connect It CC" with RCA plugs (XLR as an option). An acrylic dust cover, "Cover it 1", is also available.

Specifications

Speed: 33, 45 rpm (electronic speed change)

Drive: Belt drive

Platter: 10.4 kg aluminum (300mm diameter)

Main Bearing: inverted stainless steel with ceramic ball/plate

Wow & Flutter: 33 +/- 0.11% 45: +/- 0.10%

Speed Drift: 33: +/- 0.01% 45: +/- 0.01%

Signal to Noise: -75dB

Tonearm: 10" Carbon EVO

Effective Arm Length: 254 mm

Effective Arm Mass: 8.5 g

Overhang: 16mm

Tracking Force: 10 - 35mN

Supplied Counterweights: 5 - 7.5g / 7 - 10g / 9 - 11g / 10 - 14g

External Power Supply: 15 volts DC / 1.6A

Power Connection: 110/120 or 230/240 Volt - 50 or 60 Hz

Power Consumption: 15 watts max |

The Cliffwood was made to celebrate the heritage of VPI and to honor the city where their turntables are built. VPI teamed up with Grado Labs to engineer a cartridge shell specifically for the Grado to make it easier to mount and contribute to the sound signature.

- New 9" machined aluminum gimbal tonearm with lateral type bearing.

- 1.25" thick textured vinyl-covered non-resonant MDF chassis. Platter rotates on an oil bath bearing.

|

.jpg) Ultra-lightweight plinth

The Planar 10 is the third Rega turntable constructed using their latest technology the ultra-lightweight Tancast 8 polyurethane foam core (a material developed for the aerospace industry). This material is sandwiched between two layers of HPL (high-pressure laminate). HPL is exceptionally thin and extremely rigid. This new construction makes the new Planar 10 skeletal plinth 30% lighter than the original RP10 while offering increased rigidity over the previous model.

DB Technology (Double Brace Technology)

A super lightweight plinth combined with a ceramic top brace and phenolic resin bottom brace mounted specifically where the increased rigidity is required (between the tonearm mounting and the main hub bearing) forms a structurally sound, “stressed beam,” assembly. This rigid plinth design prevents energy absorption and unwanted resonances which will add unnatural distortions to the music. Equally, heavier mass can transfer more unwanted energy such as motor or bearing noise directly into the rotating record. The tonearm and cartridge must be able to read accurately, directly from the platter. This unique Rega double brace solution enables this. The use of braces instead of the complete skin allows increased thickness in these key areas while providing further weight reduction to the plinth which directly addresses the issue of mass absorption and unwanted energy transmission.

RB3000 tonearm

Rega is renowned for the quality of its tonearm bearing assemblies. In particular the accurate manufacturing of their bearing housing and bearing spindles. Technical characteristics such as "roundness" and "parallelity" are critical. Over the past three years, Rega has found a new manufacturing process that improves on all these characteristics resulting in a micron perfect bearing fit. The RB3000 is the first Rega arm to benefit from these improvements.

The entire tonearm structure is designed to have the minimum of mechanical joints while using the stiffest materials in all critical areas. The tolerance of the RB3000 tonearm is so tight that no adhesive is used at any point throughout the construction. Their latest low mass, precision-engineered, the vertical bearing assembly has been manufactured to further complement the inherent design philosophy of the Planar 10 turntable. The RB3000 tonearm uses Rega's advanced, preloaded zero tolerance bearing assembly adjusted to less than 1000th of a mm. This gives friction-free movement and zero levels of unwanted play. Simply put, friction-free bearings with no play enable ridges in the record groove of less than a micron to be read. The RB3000 also uses their latest award-winning, aluminum, Rega arm tube (each one of which is meticulously hand polished, keeping mass to an absolute minimum) which was redesigned to redistribute mass and further reduce stresses and resonances. This advanced design tube increases the stiffness and rigidity of the overall assembly whilst reducing stress on the bearings even further.

Hub Bearing assembly

The Planar 10 uses a new low mass central bearing assembly. A single piece of machined aluminum sub-platter and hardened tool steel spindle run inside a custom brass housing designed with improved mechanical integrity. The complete assembly is cleverly mounted within the chassis to eradicate unwanted potential energy being transferred or stored in the plinth.

Ultra-lightweight plinth

The Planar 10 is the third Rega turntable constructed using their latest technology the ultra-lightweight Tancast 8 polyurethane foam core (a material developed for the aerospace industry). This material is sandwiched between two layers of HPL (high-pressure laminate). HPL is exceptionally thin and extremely rigid. This new construction makes the new Planar 10 skeletal plinth 30% lighter than the original RP10 while offering increased rigidity over the previous model.

DB Technology (Double Brace Technology)

A super lightweight plinth combined with a ceramic top brace and phenolic resin bottom brace mounted specifically where the increased rigidity is required (between the tonearm mounting and the main hub bearing) forms a structurally sound, “stressed beam,” assembly. This rigid plinth design prevents energy absorption and unwanted resonances which will add unnatural distortions to the music. Equally, heavier mass can transfer more unwanted energy such as motor or bearing noise directly into the rotating record. The tonearm and cartridge must be able to read accurately, directly from the platter. This unique Rega double brace solution enables this. The use of braces instead of the complete skin allows increased thickness in these key areas while providing further weight reduction to the plinth which directly addresses the issue of mass absorption and unwanted energy transmission.

RB3000 tonearm

Rega is renowned for the quality of its tonearm bearing assemblies. In particular the accurate manufacturing of their bearing housing and bearing spindles. Technical characteristics such as "roundness" and "parallelity" are critical. Over the past three years, Rega has found a new manufacturing process that improves on all these characteristics resulting in a micron perfect bearing fit. The RB3000 is the first Rega arm to benefit from these improvements.

The entire tonearm structure is designed to have the minimum of mechanical joints while using the stiffest materials in all critical areas. The tolerance of the RB3000 tonearm is so tight that no adhesive is used at any point throughout the construction. Their latest low mass, precision-engineered, the vertical bearing assembly has been manufactured to further complement the inherent design philosophy of the Planar 10 turntable. The RB3000 tonearm uses Rega's advanced, preloaded zero tolerance bearing assembly adjusted to less than 1000th of a mm. This gives friction-free movement and zero levels of unwanted play. Simply put, friction-free bearings with no play enable ridges in the record groove of less than a micron to be read. The RB3000 also uses their latest award-winning, aluminum, Rega arm tube (each one of which is meticulously hand polished, keeping mass to an absolute minimum) which was redesigned to redistribute mass and further reduce stresses and resonances. This advanced design tube increases the stiffness and rigidity of the overall assembly whilst reducing stress on the bearings even further.

Hub Bearing assembly

The Planar 10 uses a new low mass central bearing assembly. A single piece of machined aluminum sub-platter and hardened tool steel spindle run inside a custom brass housing designed with improved mechanical integrity. The complete assembly is cleverly mounted within the chassis to eradicate unwanted potential energy being transferred or stored in the plinth.

Cutaway cross-section of Planar 10 bearing assembly.

Ceramic Platter

The P10 uses a custom ceramic, flywheel effect platter. The platter is produced from ceramic oxide powder which is compressed, fired and diamond cut to ensure perfect accuracy and flatness across the surface. The latest platter features a modified construction with improved coupling to the sub-platter.

24v Low noise motor assembly

The Planar 10 uses Rega's latest generation, 24v, synchronous, low vibration motor technology. Uniquely mounted using the highest level of coupling while retaining higher vibration isolation than any previous model, this new motor mounting technique (mounted from the bottom) has been taken directly from the ultimate Rega turntable, the Naiad. This unique mounting method removes all stress from the motor body whilst holding the drive pulley perfectly still. This enables better speed stability and accuracy from the turntable. The reduced vibration and more rigid mounting delivers superior drive from the new EBLT drive belts. Each motor is hand-tuned to match its own custom-matched PL10 PSU power supply before fitting to the turntable to optimize the anti-vibration circuit.

EBLT Drive Belts

For three years Rega has been researching and developing with chemists the use of a bespoke new rubber compound for drive belts. Using a specialized curing system, the new drive belt offers superior consistency of modulus (a constant representing the degree to which a substance has a particular property, especially elasticity). These new belts are manufactured on Rega designed, state of the art, super-accurate tools (inspired by working with the manufacturer of high-tech Formula 1 engine parts) which produce 'perfectly round' and 'dimensionally accurate' belts, critical for perfect speed stability.

PL10 PSU custom-matched advanced power supply.

The PL10 PSU offers the ultimate in motor control stability, convenient electronic speed change, advanced anti-vibration control, and user-adjustable electronic fine speed adjustment to ensure total accuracy and control over the life of the motor. Housed in Rega's latest custom-designed case, the PL10 PSU is dedicated to running our 24v, low noise motor as quietly and as accurately as possible. The speed and control of the motor is achieved by using a new DSP (Digital Signal Processing) generator built upon a high stability crystal. This device will divide the accurate square wave from the crystal to the exact frequency required to turn the platter at the selected speed. The DSP core will also generate a near perfect sinusoidal waveform to power the motor. Factory set vibration removal and fine speed adjustments are then made to the power supply to tune each motor for optimal performance.

Dust Cover

The outer frame of the previous model has now been removed and a new stylish, removable, single piece dustcover has been introduced further reducing the overall mass of the turntable.

Cutaway cross-section of Planar 10 bearing assembly.

Ceramic Platter

The P10 uses a custom ceramic, flywheel effect platter. The platter is produced from ceramic oxide powder which is compressed, fired and diamond cut to ensure perfect accuracy and flatness across the surface. The latest platter features a modified construction with improved coupling to the sub-platter.

24v Low noise motor assembly

The Planar 10 uses Rega's latest generation, 24v, synchronous, low vibration motor technology. Uniquely mounted using the highest level of coupling while retaining higher vibration isolation than any previous model, this new motor mounting technique (mounted from the bottom) has been taken directly from the ultimate Rega turntable, the Naiad. This unique mounting method removes all stress from the motor body whilst holding the drive pulley perfectly still. This enables better speed stability and accuracy from the turntable. The reduced vibration and more rigid mounting delivers superior drive from the new EBLT drive belts. Each motor is hand-tuned to match its own custom-matched PL10 PSU power supply before fitting to the turntable to optimize the anti-vibration circuit.

EBLT Drive Belts

For three years Rega has been researching and developing with chemists the use of a bespoke new rubber compound for drive belts. Using a specialized curing system, the new drive belt offers superior consistency of modulus (a constant representing the degree to which a substance has a particular property, especially elasticity). These new belts are manufactured on Rega designed, state of the art, super-accurate tools (inspired by working with the manufacturer of high-tech Formula 1 engine parts) which produce 'perfectly round' and 'dimensionally accurate' belts, critical for perfect speed stability.

PL10 PSU custom-matched advanced power supply.

The PL10 PSU offers the ultimate in motor control stability, convenient electronic speed change, advanced anti-vibration control, and user-adjustable electronic fine speed adjustment to ensure total accuracy and control over the life of the motor. Housed in Rega's latest custom-designed case, the PL10 PSU is dedicated to running our 24v, low noise motor as quietly and as accurately as possible. The speed and control of the motor is achieved by using a new DSP (Digital Signal Processing) generator built upon a high stability crystal. This device will divide the accurate square wave from the crystal to the exact frequency required to turn the platter at the selected speed. The DSP core will also generate a near perfect sinusoidal waveform to power the motor. Factory set vibration removal and fine speed adjustments are then made to the power supply to tune each motor for optimal performance.

Dust Cover

The outer frame of the previous model has now been removed and a new stylish, removable, single piece dustcover has been introduced further reducing the overall mass of the turntable.

Reviews

There are no reviews yet.