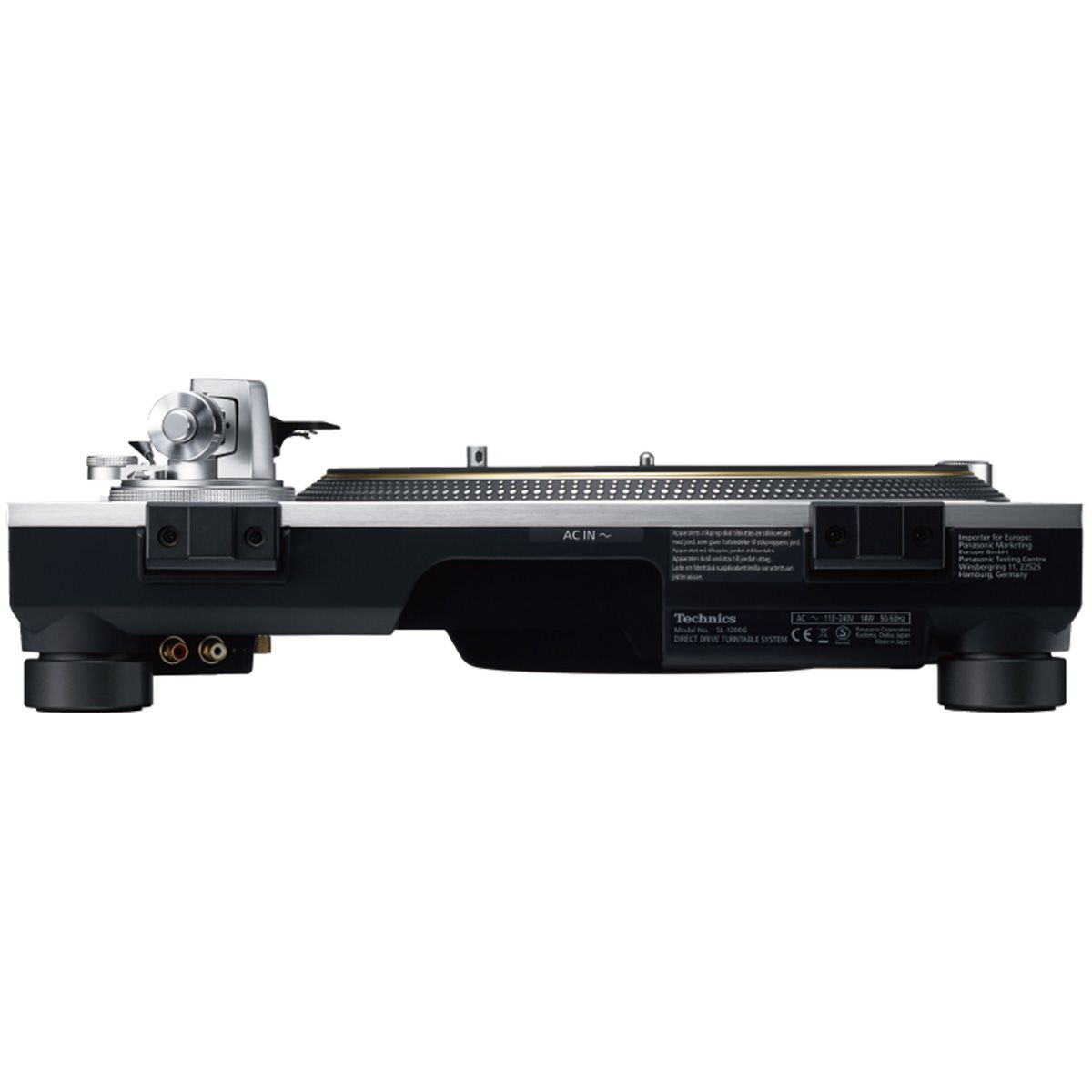

| Content | Turntable section

Type: Direct Drive Manual Turntable

Turntable Speeds: 33 1/3, 45, 78 rpm

Adjust Range: ±8%, ±16%

Starting Torque: 3.3 kg・cm (2.8 lb-in)

Build-up Characteristics: 0.7 s. from standstill to 33 1/3 r/min

Wow And Flutter: 0.025% W.R.M.S. (JIS C5521)

Rumble: 78dB (IEC 98A Weighted)

Turntable Platter:

- Brass and Aluminum diecast combined

- Diameter:332mm (13-5/64")

- Weight:About 3.6kg (7 15/16 lb) (Including rubber sheet)

Tonearm Section

Type: Universal Static Balance

Effective Length: 230mm (9-1/16")

Overhang: 15mm (19/32")

Tracking Error Angle:

- Within 2° 32' (at the outer groove of 30cm(12") record)

- Within 0° 32' (at the inner groove of 30cm(12") record)

Offset Angle: 22°

Arm-height Adjustment Range: 0 - 6 mm

Stylus Pressure Adjustment Range: 0 - 4 g (direct reading)

Terminals

Audio Output PHONO (Pin Jack) x 1

EARTH TERMINAL x 1 |

The new Classic Evo is based on the successful EISA Award winner The Classic and the experience Pro-ject won designing and building their icon turntable, the 175 VPO. The main improvement is the sub-platter, where they used the experience they gained from designing the Vienna Philharmonic Recordplayer to add key changes to the Classic Evo, adding performance features that are rarely seen in this price category. For improved comfort, an electronic speed change was built in, which lets you switch from 33 to 45 rpm (and vice versa) with the push of a button.

Compared to the old Classic, we improved the subchassis; we tried to make it heavier and stiffer to reduce resonances. Isolating the platter and tonearm from the resonances of the motor and main plinth is the target.

Platter & sub-platter

The heavy aluminium main platter construction utilises advanced thermoplastic elastomers (TPE*) for optimising resonance behaviour. A drawback for most of the old designs was the platter. Casted platters all have been heavy (which is good for speed constancy and low wow and flutter) but suffered very much from ringing effects which again caused colouration of the sound. The platter of The Classic Evo is precisely machined out of a special aluminium alloy again damped with TPE*, which offers special damping abilities. The main bearing construction we use is a similar system as the one on the Vienna Philharmonic Record player.

The diamond-cut precision alu sub-platter, like in the limited edition Vienna Philharmonic Recordplayer, enables much improved tolerances. This extraordinarily sophisticated part is accurately machined and guarantees very good isolation between bearing noise and the platter itself.

New carbon/aluminium tonearm

The radical new designed Classic tonearm is the result of 25 years of experience in mechanical construction. The tonearm tube is made out of a sandwich of carbon and aluminium: carbon for stiffness and speed, alu for better damping. The bearing has been upgraded to the same type that is used on our Pro-Ject CC EVO tonearms. It facilitates frictionless vertical and horizontal movement, guaranteeing precise tracking across the entire duration of the record. The counterweight incorporates a TPE* damper which allows us to reduce the amplitude of the tonearm cartridge resonance frequency by 50%. As typical for Pro-Ject and absolutely not standard at that price range we offer also azimuth and VTA adjustment to use a variety of cartridges.

MC Cartridge

We supply as standard the Ortofon Quintet Red moving coil cartridge. However, as the tonearm offers excellent damping and flexibility as well, its effective mass can be called middle heavy, so it is also a very good partner for MC cartridges. As the Classic is a wonderful state of the art deck, we decided to use an MC cartridge to use the potential of the player. MC cartridges are expensive, but the better choice. They are rarely used at such a price point. Pro-ject is therefore convinced to offer you an unbeatable price-performance package.

Features:

- Diamond cut precision alu sub-platter

- Improved sandwich subchassis

- Ortofon Quintet Red cartridge pre-installed

- Electronic speed control (33/45 rpm)

- Belt drive with electronic speed control 33/45 rpm

- Height adjustable decoupling feet

- Precision balanced TPE-damped aluminium-platter

- Metal/MDF sandwich chassis floating on TPE suspension

- 9” carbon/aluminium tonearm with MM & MC capability

- Inverted EVO bearing design with four ABEC7 spec ballraces

- Arm bearing housing of solid ring type. The massive outside ring is open to avoid resonances

- Azimuth and VTA fully adjustable

- TPE damped counterweight

- Classic wooden chassis in 2 satin finishes (walnut, eucalyptus)

- Dustcover included

| The Planar 10 features the new RB3000 tonearm fitted with an improved, low mass, precision bias housing. Rega has pioneered a completely new low mass, central hub bearing assembly with improved mechanical integrity. For the first time on a Rega production turntable, a ceramic top brace delivers ultimate rigidity and accuracy whilst creating the perfect platform between tonearm and central bearing. Finally, this entirely new player is controlled by their most advanced electronic power supply housed in a brand-new, full metal custom case designed to match the latest range of Rega electronics.

.jpg) Ultra-lightweight plinth

The Planar 10 is the third Rega turntable constructed using their latest technology the ultra-lightweight Tancast 8 polyurethane foam core (a material developed for the aerospace industry). This material is sandwiched between two layers of HPL (high-pressure laminate). HPL is exceptionally thin and extremely rigid. This new construction makes the new Planar 10 skeletal plinth 30% lighter than the original RP10 while offering increased rigidity over the previous model.

DB Technology (Double Brace Technology)

A super lightweight plinth combined with a ceramic top brace and phenolic resin bottom brace mounted specifically where the increased rigidity is required (between the tonearm mounting and the main hub bearing) forms a structurally sound, “stressed beam,” assembly. This rigid plinth design prevents energy absorption and unwanted resonances which will add unnatural distortions to the music. Equally, heavier mass can transfer more unwanted energy such as motor or bearing noise directly into the rotating record. The tonearm and cartridge must be able to read accurately, directly from the platter. This unique Rega double brace solution enables this. The use of braces instead of the complete skin allows increased thickness in these key areas while providing further weight reduction to the plinth which directly addresses the issue of mass absorption and unwanted energy transmission.

RB3000 tonearm

Rega is renowned for the quality of its tonearm bearing assemblies. In particular the accurate manufacturing of their bearing housing and bearing spindles. Technical characteristics such as "roundness" and "parallelity" are critical. Over the past three years, Rega has found a new manufacturing process that improves on all these characteristics resulting in a micron perfect bearing fit. The RB3000 is the first Rega arm to benefit from these improvements.

The entire tonearm structure is designed to have the minimum of mechanical joints while using the stiffest materials in all critical areas. The tolerance of the RB3000 tonearm is so tight that no adhesive is used at any point throughout the construction. Their latest low mass, precision-engineered, the vertical bearing assembly has been manufactured to further complement the inherent design philosophy of the Planar 10 turntable. The RB3000 tonearm uses Rega's advanced, preloaded zero tolerance bearing assembly adjusted to less than 1000th of a mm. This gives friction-free movement and zero levels of unwanted play. Simply put, friction-free bearings with no play enable ridges in the record groove of less than a micron to be read. The RB3000 also uses their latest award-winning, aluminum, Rega arm tube (each one of which is meticulously hand polished, keeping mass to an absolute minimum) which was redesigned to redistribute mass and further reduce stresses and resonances. This advanced design tube increases the stiffness and rigidity of the overall assembly whilst reducing stress on the bearings even further.

Hub Bearing assembly

The Planar 10 uses a new low mass central bearing assembly. A single piece of machined aluminum sub-platter and hardened tool steel spindle run inside a custom brass housing designed with improved mechanical integrity. The complete assembly is cleverly mounted within the chassis to eradicate unwanted potential energy being transferred or stored in the plinth.

Ultra-lightweight plinth

The Planar 10 is the third Rega turntable constructed using their latest technology the ultra-lightweight Tancast 8 polyurethane foam core (a material developed for the aerospace industry). This material is sandwiched between two layers of HPL (high-pressure laminate). HPL is exceptionally thin and extremely rigid. This new construction makes the new Planar 10 skeletal plinth 30% lighter than the original RP10 while offering increased rigidity over the previous model.

DB Technology (Double Brace Technology)

A super lightweight plinth combined with a ceramic top brace and phenolic resin bottom brace mounted specifically where the increased rigidity is required (between the tonearm mounting and the main hub bearing) forms a structurally sound, “stressed beam,” assembly. This rigid plinth design prevents energy absorption and unwanted resonances which will add unnatural distortions to the music. Equally, heavier mass can transfer more unwanted energy such as motor or bearing noise directly into the rotating record. The tonearm and cartridge must be able to read accurately, directly from the platter. This unique Rega double brace solution enables this. The use of braces instead of the complete skin allows increased thickness in these key areas while providing further weight reduction to the plinth which directly addresses the issue of mass absorption and unwanted energy transmission.

RB3000 tonearm

Rega is renowned for the quality of its tonearm bearing assemblies. In particular the accurate manufacturing of their bearing housing and bearing spindles. Technical characteristics such as "roundness" and "parallelity" are critical. Over the past three years, Rega has found a new manufacturing process that improves on all these characteristics resulting in a micron perfect bearing fit. The RB3000 is the first Rega arm to benefit from these improvements.

The entire tonearm structure is designed to have the minimum of mechanical joints while using the stiffest materials in all critical areas. The tolerance of the RB3000 tonearm is so tight that no adhesive is used at any point throughout the construction. Their latest low mass, precision-engineered, the vertical bearing assembly has been manufactured to further complement the inherent design philosophy of the Planar 10 turntable. The RB3000 tonearm uses Rega's advanced, preloaded zero tolerance bearing assembly adjusted to less than 1000th of a mm. This gives friction-free movement and zero levels of unwanted play. Simply put, friction-free bearings with no play enable ridges in the record groove of less than a micron to be read. The RB3000 also uses their latest award-winning, aluminum, Rega arm tube (each one of which is meticulously hand polished, keeping mass to an absolute minimum) which was redesigned to redistribute mass and further reduce stresses and resonances. This advanced design tube increases the stiffness and rigidity of the overall assembly whilst reducing stress on the bearings even further.

Hub Bearing assembly

The Planar 10 uses a new low mass central bearing assembly. A single piece of machined aluminum sub-platter and hardened tool steel spindle run inside a custom brass housing designed with improved mechanical integrity. The complete assembly is cleverly mounted within the chassis to eradicate unwanted potential energy being transferred or stored in the plinth.

Cutaway cross-section of Planar 10 bearing assembly.

Ceramic Platter

The P10 uses a custom ceramic, flywheel effect platter. The platter is produced from ceramic oxide powder which is compressed, fired and diamond cut to ensure perfect accuracy and flatness across the surface. The latest platter features a modified construction with improved coupling to the sub-platter.

24v Low noise motor assembly

The Planar 10 uses Rega's latest generation, 24v, synchronous, low vibration motor technology. Uniquely mounted using the highest level of coupling while retaining higher vibration isolation than any previous model, this new motor mounting technique (mounted from the bottom) has been taken directly from the ultimate Rega turntable, the Naiad. This unique mounting method removes all stress from the motor body whilst holding the drive pulley perfectly still. This enables better speed stability and accuracy from the turntable. The reduced vibration and more rigid mounting delivers superior drive from the new EBLT drive belts. Each motor is hand-tuned to match its own custom-matched PL10 PSU power supply before fitting to the turntable to optimize the anti-vibration circuit.

EBLT Drive Belts

For three years Rega has been researching and developing with chemists the use of a bespoke new rubber compound for drive belts. Using a specialized curing system, the new drive belt offers superior consistency of modulus (a constant representing the degree to which a substance has a particular property, especially elasticity). These new belts are manufactured on Rega designed, state of the art, super-accurate tools (inspired by working with the manufacturer of high-tech Formula 1 engine parts) which produce 'perfectly round' and 'dimensionally accurate' belts, critical for perfect speed stability.

PL10 PSU custom-matched advanced power supply.

The PL10 PSU offers the ultimate in motor control stability, convenient electronic speed change, advanced anti-vibration control, and user-adjustable electronic fine speed adjustment to ensure total accuracy and control over the life of the motor. Housed in Rega's latest custom-designed case, the PL10 PSU is dedicated to running our 24v, low noise motor as quietly and as accurately as possible. The speed and control of the motor is achieved by using a new DSP (Digital Signal Processing) generator built upon a high stability crystal. This device will divide the accurate square wave from the crystal to the exact frequency required to turn the platter at the selected speed. The DSP core will also generate a near perfect sinusoidal waveform to power the motor. Factory set vibration removal and fine speed adjustments are then made to the power supply to tune each motor for optimal performance.

Dust Cover

The outer frame of the previous model has now been removed and a new stylish, removable, single piece dustcover has been introduced further reducing the overall mass of the turntable.

Cutaway cross-section of Planar 10 bearing assembly.

Ceramic Platter

The P10 uses a custom ceramic, flywheel effect platter. The platter is produced from ceramic oxide powder which is compressed, fired and diamond cut to ensure perfect accuracy and flatness across the surface. The latest platter features a modified construction with improved coupling to the sub-platter.

24v Low noise motor assembly

The Planar 10 uses Rega's latest generation, 24v, synchronous, low vibration motor technology. Uniquely mounted using the highest level of coupling while retaining higher vibration isolation than any previous model, this new motor mounting technique (mounted from the bottom) has been taken directly from the ultimate Rega turntable, the Naiad. This unique mounting method removes all stress from the motor body whilst holding the drive pulley perfectly still. This enables better speed stability and accuracy from the turntable. The reduced vibration and more rigid mounting delivers superior drive from the new EBLT drive belts. Each motor is hand-tuned to match its own custom-matched PL10 PSU power supply before fitting to the turntable to optimize the anti-vibration circuit.

EBLT Drive Belts

For three years Rega has been researching and developing with chemists the use of a bespoke new rubber compound for drive belts. Using a specialized curing system, the new drive belt offers superior consistency of modulus (a constant representing the degree to which a substance has a particular property, especially elasticity). These new belts are manufactured on Rega designed, state of the art, super-accurate tools (inspired by working with the manufacturer of high-tech Formula 1 engine parts) which produce 'perfectly round' and 'dimensionally accurate' belts, critical for perfect speed stability.

PL10 PSU custom-matched advanced power supply.

The PL10 PSU offers the ultimate in motor control stability, convenient electronic speed change, advanced anti-vibration control, and user-adjustable electronic fine speed adjustment to ensure total accuracy and control over the life of the motor. Housed in Rega's latest custom-designed case, the PL10 PSU is dedicated to running our 24v, low noise motor as quietly and as accurately as possible. The speed and control of the motor is achieved by using a new DSP (Digital Signal Processing) generator built upon a high stability crystal. This device will divide the accurate square wave from the crystal to the exact frequency required to turn the platter at the selected speed. The DSP core will also generate a near perfect sinusoidal waveform to power the motor. Factory set vibration removal and fine speed adjustments are then made to the power supply to tune each motor for optimal performance.

Dust Cover

The outer frame of the previous model has now been removed and a new stylish, removable, single piece dustcover has been introduced further reducing the overall mass of the turntable.

- Mains voltage:

- 230 V 50/60 Hz

- 220 V 50/60Hz

- 115 V 50/60Hz

- 100 V 50/60Hz

- Power consumption: 17 W

- Fuse rating: T250 mA L (230 V / 220 V)T500 mA L (115 V / 100 V)

- Output to motor: 24 V AC bi-phase ~ 350 mA

- Speed control step size: 0.01 rpm

|

The Cliffwood was made to celebrate the heritage of VPI and to honor the city where their turntables are built. VPI teamed up with Grado Labs to engineer a cartridge shell specifically for the Grado to make it easier to mount and contribute to the sound signature.

- New 9" machined aluminum gimbal tonearm with lateral type bearing.

- 1.25" thick textured vinyl-covered non-resonant MDF chassis. Platter rotates on an oil bath bearing.

|

Building on the ground breaking Juke Box E, Juke Box S2 is taking the first audiophile all-in-one system to the next level. By changing to a more sophisticated acrylic platter and an upgraded, Pro-Ject proprietary cartridge gave the Juke Box the extra bit of audiophilia it deserves. Juke Box S2 effectively saves space by implementing a pre-amplifier and power amplifier in its chassis. With the rated 50 Watts per channel it you will be able to use your stereo speakers and enjoy realistic sound stages and great depth.

- Instant playback with super-easy setup

- Bluetooth and 1 line input

- Acrylic platter

- High contrast display on top

- Line record output

- Gold plated sockets

- Pre-adjusted tracking force & anti-skating force

- Pick it 25A cartridge, pre-mounted

- 8.6" aluminium tonearm with sapphire bearings

- Belt drive with silicone belt

- Low vibration synchronous motor & DC power supply

- Special feet for effective decoupling

- IR remote control included

| Now it’s time for the heavy lifting. The motor alone weighs in at over 5lbs. This massive AC motor sits to the side of the table, providing complete isolation, and has a pulley for the belt that is machined to .0005% tolerance to achieve perfect speed. If you find the motor heavy, wait until you pick up the platter. This 20lb. beast is made out of aluminum and damping materials. It’s 39” circumference is machined to a +/- .001” tolerance. Coupled to the hardened steel bearing, this system spins at a perfectly constant speed. We believe this characteristic is essential when trying to achieve the “live” feeling from music. If the speed is off, the music does not sound realistic. VPI’s method of mass is one of the best ways to accomplish this since the heavy platter will maintain consistency once it gets up to speed. The first time you flip the switch on the motor, you’ll hear it squelch as it torques up, but don’t let this worry you. While it sounds a bit odd, it’s normal.

The Prime’s 10” 3D tonearm is quite a feat. Ideally, a tonearm would be one single piece of material, yet until 3D printing, this has been almost impossible to manufacture. VPI was able to use anti-resonant materials, and the end result is an elegant one-piece tonearm.

The tonearm is a unipivot type, meaning it’s free to move around in all directions and only has one bearing. Many in the audio industry believe this is the most friction-free bearing around, allowing your phono cartridge to do its job. The unipivot bearing even has two side outriggers to fine tune its level position. VPI includes a 6” lightweight rod you rest in a groove on the top of the headshell section, allowing you to easily determine whether its level.

Another impressive tonearm feature is its fully adjustable VTA (vertical tracking angle), which allows you to move the tonearm in order to align the top of the phono cartridge parallel to the record surface in order to achieve the best possible sound. With most tonearms, this is done by loosening screws in the side or base to raise or lower the arm, which makes it difficult to fine-tune the height. With the VPI arm, however, you simply loosen up two large screws, then use a large round knob to move the height up or down in small increments. Just as coffee fanatics experiment with achieving the perfect grind, VTA allows audio fanatics to experiment with achieving the perfect sound. There is even the option to make minor adjustments based on the thickness of your vinyl records, and the arm has a scale so you can record the exact setting for each record.

Finally, to couple the record better to the damped platter, VTA includes a stainless steel and delrin record clamp, which simply drops down over the center spindle to hold down the record.

At Audio Advice, we’re very particular about cables included with turntables. Since the signal coming out of your phono cartridge is extremely low in output, it’s necessary to use a higher-end set of cables so nothing is lost in the transfer of the signal from your turntable to the phono preamp. The Prime does not come with cables, which we actually prefer, since it allows you to choose from any of the aftermarket cables on the market today. Your choices are unlimited and whatever model you select will fit firmly onto the high-end RCA jacks found on the back of your Prime table.

One final word of advice: you must ensure your Prime is set up by a professional. They can mount and align the cartridge perfectly, and should also preset the VTA to the right height for an average record. From there, all you need to do is put it back together and set the recommended tracking force.

Performance

To check out the Prime, we used it with the Soundsmith Zephyr MIMC cartridge. Like VPI, Soundsmith has been around for over 30 years and is actually made in the USA right down the road from VPI in Peekskill, NY. This is a $1,749 low output moving iron cartridge. The Zephyr was very easy to get setup properly with it’s square body. It also has very good channel separation.

One of our favorite test LPs is Cat Stevens Tea for the Tillerman and the Prime perfectly captures his somewhat gravelly voice. The first cut, “Where Do the Children Play,” has a variety of sounds and rhythm changes that are a noteworthy test for a high-end turntable. In the first 5 seconds, you can tell the Prime is special. we’ve never heard bass notes reach down so low while maintaining such a realistic tonal quality. This same track has some very close mic’d guitar lines throughout the song. There are actually two guitars playing which on some rigs is hard to distinguish. Not so on the Prime! They each stand out alone even when things really build up towards the end of the track.

The 3D arm really lets your phono cartridge do its job, too. Once everything was set up we were not able to detect a shred of cartridge mistracking. In terms of dynamics, the percussion sounds explode to life with the Prime. After critically listening to a few more tracks, we ended up turning off the lights and putting on an old favorite, the first Chicago Album, CTA. We were instantly immersed in the music. The 3D representation afforded by the Prime is almost spooky.

As we played more records, we found the presentation of the music on almost every recording was extending wider left to right than our speakers. We believe part of this is the outstanding audio quality of the Zephyr MIMC, but if the table and tonearm are not going a great job, you would never get that type of soundstage. The Zephyr is certainly a great match for this outstanding turntable. The combination produced deep rich bass, with a high-end extension that was never harsh -- always smooth and liquid.

- 10-inch 3D Tonearm

- VTA Tower included

- Classic 20-pound platter and bearing

- Four solid Delrin corner assemblies designed for isolation and mechanical grounding

|

.jpg) Ultra-lightweight plinth

The Planar 10 is the third Rega turntable constructed using their latest technology the ultra-lightweight Tancast 8 polyurethane foam core (a material developed for the aerospace industry). This material is sandwiched between two layers of HPL (high-pressure laminate). HPL is exceptionally thin and extremely rigid. This new construction makes the new Planar 10 skeletal plinth 30% lighter than the original RP10 while offering increased rigidity over the previous model.

DB Technology (Double Brace Technology)

A super lightweight plinth combined with a ceramic top brace and phenolic resin bottom brace mounted specifically where the increased rigidity is required (between the tonearm mounting and the main hub bearing) forms a structurally sound, “stressed beam,” assembly. This rigid plinth design prevents energy absorption and unwanted resonances which will add unnatural distortions to the music. Equally, heavier mass can transfer more unwanted energy such as motor or bearing noise directly into the rotating record. The tonearm and cartridge must be able to read accurately, directly from the platter. This unique Rega double brace solution enables this. The use of braces instead of the complete skin allows increased thickness in these key areas while providing further weight reduction to the plinth which directly addresses the issue of mass absorption and unwanted energy transmission.

RB3000 tonearm

Rega is renowned for the quality of its tonearm bearing assemblies. In particular the accurate manufacturing of their bearing housing and bearing spindles. Technical characteristics such as "roundness" and "parallelity" are critical. Over the past three years, Rega has found a new manufacturing process that improves on all these characteristics resulting in a micron perfect bearing fit. The RB3000 is the first Rega arm to benefit from these improvements.

The entire tonearm structure is designed to have the minimum of mechanical joints while using the stiffest materials in all critical areas. The tolerance of the RB3000 tonearm is so tight that no adhesive is used at any point throughout the construction. Their latest low mass, precision-engineered, the vertical bearing assembly has been manufactured to further complement the inherent design philosophy of the Planar 10 turntable. The RB3000 tonearm uses Rega's advanced, preloaded zero tolerance bearing assembly adjusted to less than 1000th of a mm. This gives friction-free movement and zero levels of unwanted play. Simply put, friction-free bearings with no play enable ridges in the record groove of less than a micron to be read. The RB3000 also uses their latest award-winning, aluminum, Rega arm tube (each one of which is meticulously hand polished, keeping mass to an absolute minimum) which was redesigned to redistribute mass and further reduce stresses and resonances. This advanced design tube increases the stiffness and rigidity of the overall assembly whilst reducing stress on the bearings even further.

Hub Bearing assembly

The Planar 10 uses a new low mass central bearing assembly. A single piece of machined aluminum sub-platter and hardened tool steel spindle run inside a custom brass housing designed with improved mechanical integrity. The complete assembly is cleverly mounted within the chassis to eradicate unwanted potential energy being transferred or stored in the plinth.

Ultra-lightweight plinth

The Planar 10 is the third Rega turntable constructed using their latest technology the ultra-lightweight Tancast 8 polyurethane foam core (a material developed for the aerospace industry). This material is sandwiched between two layers of HPL (high-pressure laminate). HPL is exceptionally thin and extremely rigid. This new construction makes the new Planar 10 skeletal plinth 30% lighter than the original RP10 while offering increased rigidity over the previous model.

DB Technology (Double Brace Technology)

A super lightweight plinth combined with a ceramic top brace and phenolic resin bottom brace mounted specifically where the increased rigidity is required (between the tonearm mounting and the main hub bearing) forms a structurally sound, “stressed beam,” assembly. This rigid plinth design prevents energy absorption and unwanted resonances which will add unnatural distortions to the music. Equally, heavier mass can transfer more unwanted energy such as motor or bearing noise directly into the rotating record. The tonearm and cartridge must be able to read accurately, directly from the platter. This unique Rega double brace solution enables this. The use of braces instead of the complete skin allows increased thickness in these key areas while providing further weight reduction to the plinth which directly addresses the issue of mass absorption and unwanted energy transmission.

RB3000 tonearm

Rega is renowned for the quality of its tonearm bearing assemblies. In particular the accurate manufacturing of their bearing housing and bearing spindles. Technical characteristics such as "roundness" and "parallelity" are critical. Over the past three years, Rega has found a new manufacturing process that improves on all these characteristics resulting in a micron perfect bearing fit. The RB3000 is the first Rega arm to benefit from these improvements.

The entire tonearm structure is designed to have the minimum of mechanical joints while using the stiffest materials in all critical areas. The tolerance of the RB3000 tonearm is so tight that no adhesive is used at any point throughout the construction. Their latest low mass, precision-engineered, the vertical bearing assembly has been manufactured to further complement the inherent design philosophy of the Planar 10 turntable. The RB3000 tonearm uses Rega's advanced, preloaded zero tolerance bearing assembly adjusted to less than 1000th of a mm. This gives friction-free movement and zero levels of unwanted play. Simply put, friction-free bearings with no play enable ridges in the record groove of less than a micron to be read. The RB3000 also uses their latest award-winning, aluminum, Rega arm tube (each one of which is meticulously hand polished, keeping mass to an absolute minimum) which was redesigned to redistribute mass and further reduce stresses and resonances. This advanced design tube increases the stiffness and rigidity of the overall assembly whilst reducing stress on the bearings even further.

Hub Bearing assembly

The Planar 10 uses a new low mass central bearing assembly. A single piece of machined aluminum sub-platter and hardened tool steel spindle run inside a custom brass housing designed with improved mechanical integrity. The complete assembly is cleverly mounted within the chassis to eradicate unwanted potential energy being transferred or stored in the plinth.

Cutaway cross-section of Planar 10 bearing assembly.

Ceramic Platter

The P10 uses a custom ceramic, flywheel effect platter. The platter is produced from ceramic oxide powder which is compressed, fired and diamond cut to ensure perfect accuracy and flatness across the surface. The latest platter features a modified construction with improved coupling to the sub-platter.

24v Low noise motor assembly

The Planar 10 uses Rega's latest generation, 24v, synchronous, low vibration motor technology. Uniquely mounted using the highest level of coupling while retaining higher vibration isolation than any previous model, this new motor mounting technique (mounted from the bottom) has been taken directly from the ultimate Rega turntable, the Naiad. This unique mounting method removes all stress from the motor body whilst holding the drive pulley perfectly still. This enables better speed stability and accuracy from the turntable. The reduced vibration and more rigid mounting delivers superior drive from the new EBLT drive belts. Each motor is hand-tuned to match its own custom-matched PL10 PSU power supply before fitting to the turntable to optimize the anti-vibration circuit.

EBLT Drive Belts

For three years Rega has been researching and developing with chemists the use of a bespoke new rubber compound for drive belts. Using a specialized curing system, the new drive belt offers superior consistency of modulus (a constant representing the degree to which a substance has a particular property, especially elasticity). These new belts are manufactured on Rega designed, state of the art, super-accurate tools (inspired by working with the manufacturer of high-tech Formula 1 engine parts) which produce 'perfectly round' and 'dimensionally accurate' belts, critical for perfect speed stability.

PL10 PSU custom-matched advanced power supply.

The PL10 PSU offers the ultimate in motor control stability, convenient electronic speed change, advanced anti-vibration control, and user-adjustable electronic fine speed adjustment to ensure total accuracy and control over the life of the motor. Housed in Rega's latest custom-designed case, the PL10 PSU is dedicated to running our 24v, low noise motor as quietly and as accurately as possible. The speed and control of the motor is achieved by using a new DSP (Digital Signal Processing) generator built upon a high stability crystal. This device will divide the accurate square wave from the crystal to the exact frequency required to turn the platter at the selected speed. The DSP core will also generate a near perfect sinusoidal waveform to power the motor. Factory set vibration removal and fine speed adjustments are then made to the power supply to tune each motor for optimal performance.

Dust Cover

The outer frame of the previous model has now been removed and a new stylish, removable, single piece dustcover has been introduced further reducing the overall mass of the turntable.

Cutaway cross-section of Planar 10 bearing assembly.

Ceramic Platter

The P10 uses a custom ceramic, flywheel effect platter. The platter is produced from ceramic oxide powder which is compressed, fired and diamond cut to ensure perfect accuracy and flatness across the surface. The latest platter features a modified construction with improved coupling to the sub-platter.

24v Low noise motor assembly

The Planar 10 uses Rega's latest generation, 24v, synchronous, low vibration motor technology. Uniquely mounted using the highest level of coupling while retaining higher vibration isolation than any previous model, this new motor mounting technique (mounted from the bottom) has been taken directly from the ultimate Rega turntable, the Naiad. This unique mounting method removes all stress from the motor body whilst holding the drive pulley perfectly still. This enables better speed stability and accuracy from the turntable. The reduced vibration and more rigid mounting delivers superior drive from the new EBLT drive belts. Each motor is hand-tuned to match its own custom-matched PL10 PSU power supply before fitting to the turntable to optimize the anti-vibration circuit.

EBLT Drive Belts

For three years Rega has been researching and developing with chemists the use of a bespoke new rubber compound for drive belts. Using a specialized curing system, the new drive belt offers superior consistency of modulus (a constant representing the degree to which a substance has a particular property, especially elasticity). These new belts are manufactured on Rega designed, state of the art, super-accurate tools (inspired by working with the manufacturer of high-tech Formula 1 engine parts) which produce 'perfectly round' and 'dimensionally accurate' belts, critical for perfect speed stability.

PL10 PSU custom-matched advanced power supply.

The PL10 PSU offers the ultimate in motor control stability, convenient electronic speed change, advanced anti-vibration control, and user-adjustable electronic fine speed adjustment to ensure total accuracy and control over the life of the motor. Housed in Rega's latest custom-designed case, the PL10 PSU is dedicated to running our 24v, low noise motor as quietly and as accurately as possible. The speed and control of the motor is achieved by using a new DSP (Digital Signal Processing) generator built upon a high stability crystal. This device will divide the accurate square wave from the crystal to the exact frequency required to turn the platter at the selected speed. The DSP core will also generate a near perfect sinusoidal waveform to power the motor. Factory set vibration removal and fine speed adjustments are then made to the power supply to tune each motor for optimal performance.

Dust Cover

The outer frame of the previous model has now been removed and a new stylish, removable, single piece dustcover has been introduced further reducing the overall mass of the turntable.

Reviews

There are no reviews yet.