| Content | Turntable section

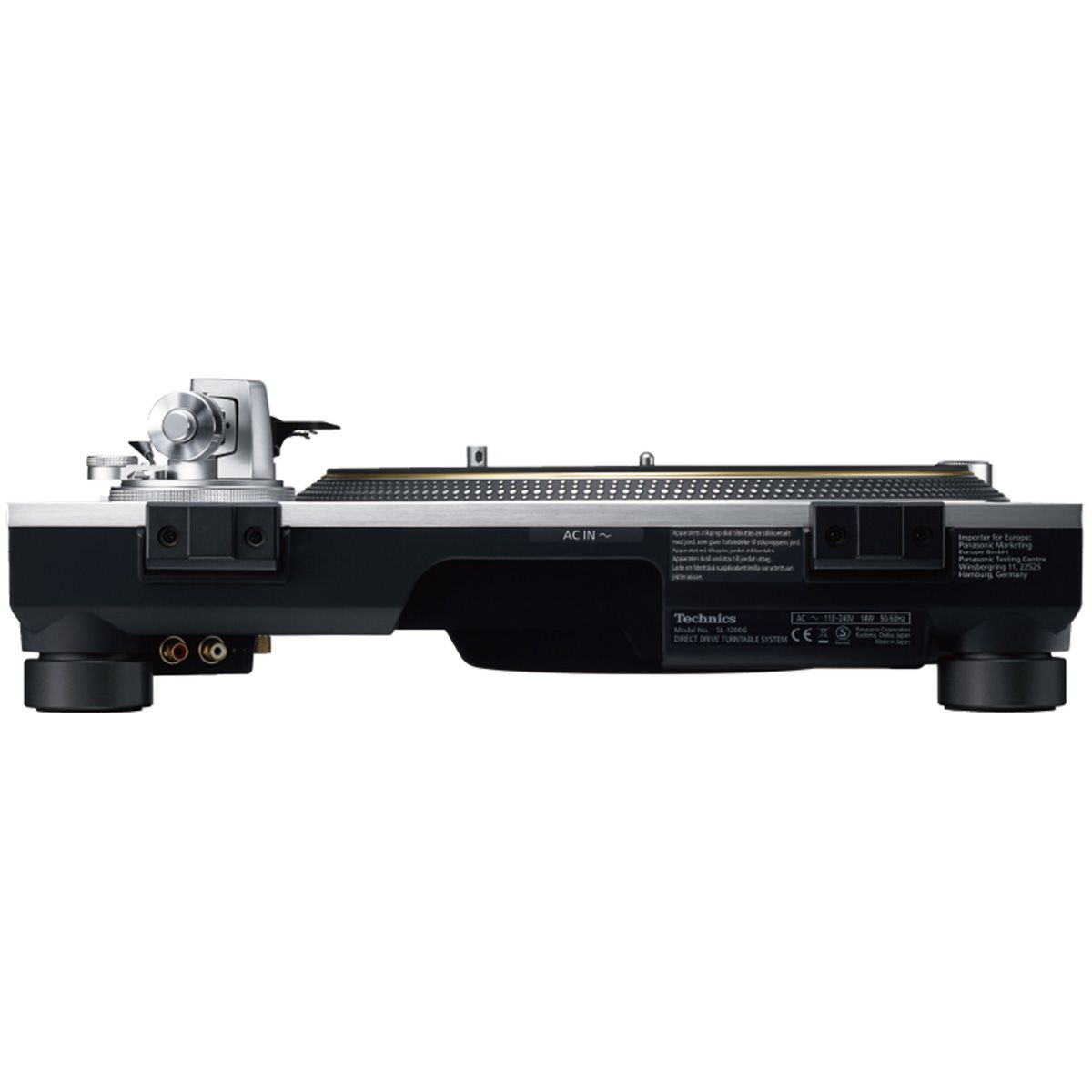

Type: Direct Drive Manual Turntable

Turntable Speeds: 33 1/3, 45, 78 rpm

Adjust Range: ±8%, ±16%

Starting Torque: 3.3 kg・cm (2.8 lb-in)

Build-up Characteristics: 0.7 s. from standstill to 33 1/3 r/min

Wow And Flutter: 0.025% W.R.M.S. (JIS C5521)

Rumble: 78dB (IEC 98A Weighted)

Turntable Platter:

- Brass and Aluminum diecast combined

- Diameter:332mm (13-5/64")

- Weight:About 3.6kg (7 15/16 lb) (Including rubber sheet)

Tonearm Section

Type: Universal Static Balance

Effective Length: 230mm (9-1/16")

Overhang: 15mm (19/32")

Tracking Error Angle:

- Within 2° 32' (at the outer groove of 30cm(12") record)

- Within 0° 32' (at the inner groove of 30cm(12") record)

Offset Angle: 22°

Arm-height Adjustment Range: 0 - 6 mm

Stylus Pressure Adjustment Range: 0 - 4 g (direct reading)

Terminals

Audio Output PHONO (Pin Jack) x 1

EARTH TERMINAL x 1 |

The B-Sharp sheds all of the non-essential cosmetic adornments of the C-Major without compromising performance or mechanical integrity, providing vinyl enthusiasts with a superb playback option at a more affordable price.

- Features the new B-Note tonearm, made from a carbon fiber alloy that is light yet rigid with a black anodized aluminum headshell. The B-Note tonearm provides all of the key features for cartridge alignment and adjustability: VTA (Vertical Tracking Angle), SRA (Stylus Rake Angle), VTF (Vertical Tracking Force), azimuth and a slotted headshell for overhang / offset angle.

- The anti-skate mechanism has been engineered for more intuitive calibration, making setup of the B-Sharp notably easier than competitive products.

- A proprietary low noise motor, floating chassis, aluminum platter and a high-density MDF low profile base are included as standard features of the B-Sharp. Like the C-Major, the B-Sharp uses a high-tech TPE (thermoplastic elastomers) suspension system that works in concert with adjustable feet that provide levelling ability for the table.

- Comes equipped with a factory installed Ortofon 2M Blue Cartridge, hinged dustcover, low mass aluminum record clamp, and a felt platter mat-all included.

|

Designing a new turntable to celebrate VPI's 40th anniversary provided VPI an opportunity to update the direct drive motor technology to incorporate advances in motion control and materials technologies.

Harry Weisfeld's 2012 CLASSIC DIRECT direct drive turntable was an outstanding technical achievement, earning Stereophile Magazine's Class A+ rating. This award-winning table was loosely based on the VPI Classic Series table technology and included a thick aluminum plinth and armboard and an inverted platter bearing riding on a PEEK thrust disc. Combined with a cutting-edge BLDC direct drive motor, the CLASSIC DIRECT was created. The Classic Direct provided a stable, solid foundation for the music, allowing the listener to hear deeply into the recorded grooves to the treasures buried with-in!

|

The B-Sharp sheds all of the non-essential cosmetic adornments of the C-Major without compromising performance or mechanical integrity, providing vinyl enthusiasts with a superb playback option at a more affordable price.

- Features the new B-Note tonearm, made from a carbon fiber alloy that is light yet rigid with a black anodized aluminum headshell. The B-Note tonearm provides all of the key features for cartridge alignment and adjustability: VTA (Vertical Tracking Angle), SRA (Stylus Rake Angle), VTF (Vertical Tracking Force), azimuth and a slotted headshell for overhang / offset angle.

- The anti-skate mechanism has been engineered for more intuitive calibration, making setup of the B-Sharp notably easier than competitive products.

- A proprietary low noise motor, floating chassis, aluminum platter and a high-density MDF low profile base are included as standard features of the B-Sharp. Like the C-Major, the B-Sharp uses a high-tech TPE (thermoplastic elastomers) suspension system that works in concert with adjustable feet that provide levelling ability for the table.

- Comes equipped with a factory installed Ortofon 2M Blue Cartridge, hinged dustcover, low mass aluminum record clamp, and a felt platter mat-all included.

| The C-Major is EAT's best value turntable, incorporating many of the design features of the more expensive C-Sharp. You'll get a heavy platter for great speed stability, a solid record clamp, and the C-Note 9" tonearm, which uses very precision bearings. Combine this with the included $500 Ortofon Quintet Blue cartridge and fitted dustcover, and you will be getting a real value. This package will bring all your vinyl to life and give you many years of listening pleasure.

Design & Build Quality

The first time that we had a chance to play with the EAT turntables there were a couple of things that really impressed us right off the bat. Their striking appearance will obviously catch your attention. We’ve even had several happy EAT customers tell us that when they first got their table out of the box they just stared at it in awe. Once you start to put the table together, however, you will immediately get a great sense of the superb craftsmanship.

The EAT C-Major has a very similar look to the C-Sharp -- the same low slung body and mix of high gloss black, carbon fiber, and brushed aluminum which make many of the other tables on the market look chunky in comparison. The plinth is made of carbon fiber and is nestled on some floating isolators inside a thin, high-gloss black base. The C-Major’s 9” tonearm features a carbon fiber arm tube and the heavy platter supports a special mat that is made from recycled LPs. It’s then topped off with a substantial record clamp. The whole combination just looks fantastic!

Like all great turntables, the C-Major is a fully manual turntable. You might think that a high-end table like this would be difficult to use, but we were pleasantly surprised to discover that it’s just the opposite! You simply turn it on, move the tonearm over the record, lower it down, and enjoy the tunes!

Features & Technology

We’ll start from the bottom of the table and work our way up. The sleek and slim base is made out of a super dense MDF material. Inside, the low-noise motor is mounted to the lower sub-chassis which is isolated from the upper plinth with eight cone-shaped pieces of a high tech damping material called Thermoplastic Elastomer, or TPE. These provide great isolation from the motor and really do a great job damping out external vibrations. If you want to feel the damping effect, simply push down gently on the plinth.

The plinth is made from an outer shell of carbon fiber sandwiched over MDF. The C-Major has three adjustable feet which make leveling everything a snap. The feet are also internally damped to reduce any external noise from getting up to the table. The EAT also includes a low profile dust cover with the C-Major, which not only protects it, but also matches up with its sleek appearance.

The bearing for the inner platter is pretty similar to what you find in most turntables in this category. The inner platter has a shaft that drops into a bronze bearing well where its tip spins on a special plate made of a near friction-free, teflon-like material.

The outer platter weighs in at a stout 4 lbs and has a great design. The top part that touches the record is made out of recycled vinyl, while the rest of the platter is a sandwich design of an aluminum/magnesium alloy with TPE in the center. EAT puts more mass on the outer edge of the platter, which helps to give it a great flywheel effect. This combination of bearing and platter is one reason the EAT tables all have great speed consistency. Like the more expensive C-Sharp, the C-major also comes with an aluminum record clamp.

While there are lots of things we love about this table, one of our favorite aspects is the carbon fiber tonearm that we mentioned earlier. It’s incredibly adjustable, allowing you to use a wide range of phono cartridges on it. These adjustments exude European precision.

The design of the tonearm is a combination of a uni-pivot and a more conventional Carden type.

Uni-pivot arms can move freely, not only across the record and up and down, but also rotating on the horizontal plane. Imagine an airplane coming in for a landing when you see the wings move up and down on each side in relation to the ground. The theory is there is some movement like this in the record grooves and being able to have freedom of movement allows the cartridge to track better.

The downside of uni-pivots is they are a royal pain to adjust. EAT came up with a brilliant solution that gives you the best of both worlds and we can attest to the fact that it works great! You get a small amount of movement where the arm can tip left to right, but it behaves more like a traditional pivoted arm.

The rear counterweight has an additional weighted insert that you can install for cartridges that are heavier than normal. The counterweight doesn’t have any markings like a lot of high end tonearms, so you will need a stylus pressure gauge to set the right force, but luckily EAT includes one in the box.

You also have azimuth adjustment which allows you to adjust the tonearm left and right. When you look at your tonearm from the front while sitting on a record, the headshell should be parallel to the record surface. EAT lets you really fine tune this if you desire. Finally, you can even adjust the height of the tonearm rest and the cueing cylinder, allowing you to really dial things in for your cartridge.

For anti-skating, EAT uses a gravity-based system which we really like. It is a little bit of a pain to set up, but we’ve been able to help everyone through it, so if you purchase one and have any trouble, just give us a call.

Finally, to change from 33 to 45, like a lot of tables out there, you simply lift off the outer platter and move the belt on the motor pulley.

Please don’t let all of these adjustments make you think this table is finicky or hard to set up. The best way to buy it is with the deal EAT has on the Ortofon Blue, Black MC, or their own JO5. These all come preset up and you save quite a bit with the package -- $250 or $500, which makes the table an amazing deal!

Performance

To test out the EAT C-Major, we set up what we thought might be a typical rig. We used the Cambridge CXA80 integrated amp, a Sutherland KC Vibe phono stage and a pair of Paradigm’s new Premier 800F towers. The table used the Ortofon Blue, which we think is probably the best way to go for the money with the C-Major.

First up was the classic Landside from Fleetwood Mac. When you have a great system that is well set up Stevie Nick’s voice should be dead center while the guitars float in between the speakers. This combo aced this test!

Next up was Robbie Robertson’s Somewhere Down the Crazy River from his first solo album in 1987. We look for two things on this one. First, there are some very dynamic bass attacks as the track begins. Then later on, you can hear lots of emotion in his voice when he says "Why do you always end up down at Nick's Cafe?" , "I don't know, the wind just kind of pushed me this way." It’s in the first “why” and “pushed me this way” on a great system you’ll hear all kinds of subtle inflections in his voice. While we have heard more on much more expensive rigs, this combination once again, really drew us into the music. Plus, it nailed the bass attacks.

After hearing this, we wanted to pull out our favorite cut for testing speed stability. This is Pink Houses from John Cougar's Uh-Huh album. If the table has great speed stability, you’ll be tapping your foot to the music. Once again, the EAT was very impressive.

This is one very special table. It has the ability with its precision tonearm to track really well and its isolation system helps it provide that great bass impact. EAT designs are also winning us over for their speed purity. Finally, with its jewel of a tonearm, it's just fun to use!

- The C-Note tonearm on the C-Major is 9" in length instead of 10" on the C-Sharp

- There is no separate speed control

- The main chassis has a more compact footprint

- The platter clamp is smaller

- The platter is smaller

| The Planar 10 features the new RB3000 tonearm fitted with an improved, low mass, precision bias housing. Rega has pioneered a completely new low mass, central hub bearing assembly with improved mechanical integrity. For the first time on a Rega production turntable, a ceramic top brace delivers ultimate rigidity and accuracy whilst creating the perfect platform between tonearm and central bearing. Finally, this entirely new player is controlled by their most advanced electronic power supply housed in a brand-new, full metal custom case designed to match the latest range of Rega electronics.

.jpg) Ultra-lightweight plinth

The Planar 10 is the third Rega turntable constructed using their latest technology the ultra-lightweight Tancast 8 polyurethane foam core (a material developed for the aerospace industry). This material is sandwiched between two layers of HPL (high-pressure laminate). HPL is exceptionally thin and extremely rigid. This new construction makes the new Planar 10 skeletal plinth 30% lighter than the original RP10 while offering increased rigidity over the previous model.

DB Technology (Double Brace Technology)

A super lightweight plinth combined with a ceramic top brace and phenolic resin bottom brace mounted specifically where the increased rigidity is required (between the tonearm mounting and the main hub bearing) forms a structurally sound, “stressed beam,” assembly. This rigid plinth design prevents energy absorption and unwanted resonances which will add unnatural distortions to the music. Equally, heavier mass can transfer more unwanted energy such as motor or bearing noise directly into the rotating record. The tonearm and cartridge must be able to read accurately, directly from the platter. This unique Rega double brace solution enables this. The use of braces instead of the complete skin allows increased thickness in these key areas while providing further weight reduction to the plinth which directly addresses the issue of mass absorption and unwanted energy transmission.

RB3000 tonearm

Rega is renowned for the quality of its tonearm bearing assemblies. In particular the accurate manufacturing of their bearing housing and bearing spindles. Technical characteristics such as "roundness" and "parallelity" are critical. Over the past three years, Rega has found a new manufacturing process that improves on all these characteristics resulting in a micron perfect bearing fit. The RB3000 is the first Rega arm to benefit from these improvements.

The entire tonearm structure is designed to have the minimum of mechanical joints while using the stiffest materials in all critical areas. The tolerance of the RB3000 tonearm is so tight that no adhesive is used at any point throughout the construction. Their latest low mass, precision-engineered, the vertical bearing assembly has been manufactured to further complement the inherent design philosophy of the Planar 10 turntable. The RB3000 tonearm uses Rega's advanced, preloaded zero tolerance bearing assembly adjusted to less than 1000th of a mm. This gives friction-free movement and zero levels of unwanted play. Simply put, friction-free bearings with no play enable ridges in the record groove of less than a micron to be read. The RB3000 also uses their latest award-winning, aluminum, Rega arm tube (each one of which is meticulously hand polished, keeping mass to an absolute minimum) which was redesigned to redistribute mass and further reduce stresses and resonances. This advanced design tube increases the stiffness and rigidity of the overall assembly whilst reducing stress on the bearings even further.

Hub Bearing assembly

The Planar 10 uses a new low mass central bearing assembly. A single piece of machined aluminum sub-platter and hardened tool steel spindle run inside a custom brass housing designed with improved mechanical integrity. The complete assembly is cleverly mounted within the chassis to eradicate unwanted potential energy being transferred or stored in the plinth.

Ultra-lightweight plinth

The Planar 10 is the third Rega turntable constructed using their latest technology the ultra-lightweight Tancast 8 polyurethane foam core (a material developed for the aerospace industry). This material is sandwiched between two layers of HPL (high-pressure laminate). HPL is exceptionally thin and extremely rigid. This new construction makes the new Planar 10 skeletal plinth 30% lighter than the original RP10 while offering increased rigidity over the previous model.

DB Technology (Double Brace Technology)

A super lightweight plinth combined with a ceramic top brace and phenolic resin bottom brace mounted specifically where the increased rigidity is required (between the tonearm mounting and the main hub bearing) forms a structurally sound, “stressed beam,” assembly. This rigid plinth design prevents energy absorption and unwanted resonances which will add unnatural distortions to the music. Equally, heavier mass can transfer more unwanted energy such as motor or bearing noise directly into the rotating record. The tonearm and cartridge must be able to read accurately, directly from the platter. This unique Rega double brace solution enables this. The use of braces instead of the complete skin allows increased thickness in these key areas while providing further weight reduction to the plinth which directly addresses the issue of mass absorption and unwanted energy transmission.

RB3000 tonearm

Rega is renowned for the quality of its tonearm bearing assemblies. In particular the accurate manufacturing of their bearing housing and bearing spindles. Technical characteristics such as "roundness" and "parallelity" are critical. Over the past three years, Rega has found a new manufacturing process that improves on all these characteristics resulting in a micron perfect bearing fit. The RB3000 is the first Rega arm to benefit from these improvements.

The entire tonearm structure is designed to have the minimum of mechanical joints while using the stiffest materials in all critical areas. The tolerance of the RB3000 tonearm is so tight that no adhesive is used at any point throughout the construction. Their latest low mass, precision-engineered, the vertical bearing assembly has been manufactured to further complement the inherent design philosophy of the Planar 10 turntable. The RB3000 tonearm uses Rega's advanced, preloaded zero tolerance bearing assembly adjusted to less than 1000th of a mm. This gives friction-free movement and zero levels of unwanted play. Simply put, friction-free bearings with no play enable ridges in the record groove of less than a micron to be read. The RB3000 also uses their latest award-winning, aluminum, Rega arm tube (each one of which is meticulously hand polished, keeping mass to an absolute minimum) which was redesigned to redistribute mass and further reduce stresses and resonances. This advanced design tube increases the stiffness and rigidity of the overall assembly whilst reducing stress on the bearings even further.

Hub Bearing assembly

The Planar 10 uses a new low mass central bearing assembly. A single piece of machined aluminum sub-platter and hardened tool steel spindle run inside a custom brass housing designed with improved mechanical integrity. The complete assembly is cleverly mounted within the chassis to eradicate unwanted potential energy being transferred or stored in the plinth.

Cutaway cross-section of Planar 10 bearing assembly.

Ceramic Platter

The P10 uses a custom ceramic, flywheel effect platter. The platter is produced from ceramic oxide powder which is compressed, fired and diamond cut to ensure perfect accuracy and flatness across the surface. The latest platter features a modified construction with improved coupling to the sub-platter.

24v Low noise motor assembly

The Planar 10 uses Rega's latest generation, 24v, synchronous, low vibration motor technology. Uniquely mounted using the highest level of coupling while retaining higher vibration isolation than any previous model, this new motor mounting technique (mounted from the bottom) has been taken directly from the ultimate Rega turntable, the Naiad. This unique mounting method removes all stress from the motor body whilst holding the drive pulley perfectly still. This enables better speed stability and accuracy from the turntable. The reduced vibration and more rigid mounting delivers superior drive from the new EBLT drive belts. Each motor is hand-tuned to match its own custom-matched PL10 PSU power supply before fitting to the turntable to optimize the anti-vibration circuit.

EBLT Drive Belts

For three years Rega has been researching and developing with chemists the use of a bespoke new rubber compound for drive belts. Using a specialized curing system, the new drive belt offers superior consistency of modulus (a constant representing the degree to which a substance has a particular property, especially elasticity). These new belts are manufactured on Rega designed, state of the art, super-accurate tools (inspired by working with the manufacturer of high-tech Formula 1 engine parts) which produce 'perfectly round' and 'dimensionally accurate' belts, critical for perfect speed stability.

PL10 PSU custom-matched advanced power supply.

The PL10 PSU offers the ultimate in motor control stability, convenient electronic speed change, advanced anti-vibration control, and user-adjustable electronic fine speed adjustment to ensure total accuracy and control over the life of the motor. Housed in Rega's latest custom-designed case, the PL10 PSU is dedicated to running our 24v, low noise motor as quietly and as accurately as possible. The speed and control of the motor is achieved by using a new DSP (Digital Signal Processing) generator built upon a high stability crystal. This device will divide the accurate square wave from the crystal to the exact frequency required to turn the platter at the selected speed. The DSP core will also generate a near perfect sinusoidal waveform to power the motor. Factory set vibration removal and fine speed adjustments are then made to the power supply to tune each motor for optimal performance.

Dust Cover

The outer frame of the previous model has now been removed and a new stylish, removable, single piece dustcover has been introduced further reducing the overall mass of the turntable.

Cutaway cross-section of Planar 10 bearing assembly.

Ceramic Platter

The P10 uses a custom ceramic, flywheel effect platter. The platter is produced from ceramic oxide powder which is compressed, fired and diamond cut to ensure perfect accuracy and flatness across the surface. The latest platter features a modified construction with improved coupling to the sub-platter.

24v Low noise motor assembly

The Planar 10 uses Rega's latest generation, 24v, synchronous, low vibration motor technology. Uniquely mounted using the highest level of coupling while retaining higher vibration isolation than any previous model, this new motor mounting technique (mounted from the bottom) has been taken directly from the ultimate Rega turntable, the Naiad. This unique mounting method removes all stress from the motor body whilst holding the drive pulley perfectly still. This enables better speed stability and accuracy from the turntable. The reduced vibration and more rigid mounting delivers superior drive from the new EBLT drive belts. Each motor is hand-tuned to match its own custom-matched PL10 PSU power supply before fitting to the turntable to optimize the anti-vibration circuit.

EBLT Drive Belts

For three years Rega has been researching and developing with chemists the use of a bespoke new rubber compound for drive belts. Using a specialized curing system, the new drive belt offers superior consistency of modulus (a constant representing the degree to which a substance has a particular property, especially elasticity). These new belts are manufactured on Rega designed, state of the art, super-accurate tools (inspired by working with the manufacturer of high-tech Formula 1 engine parts) which produce 'perfectly round' and 'dimensionally accurate' belts, critical for perfect speed stability.

PL10 PSU custom-matched advanced power supply.

The PL10 PSU offers the ultimate in motor control stability, convenient electronic speed change, advanced anti-vibration control, and user-adjustable electronic fine speed adjustment to ensure total accuracy and control over the life of the motor. Housed in Rega's latest custom-designed case, the PL10 PSU is dedicated to running our 24v, low noise motor as quietly and as accurately as possible. The speed and control of the motor is achieved by using a new DSP (Digital Signal Processing) generator built upon a high stability crystal. This device will divide the accurate square wave from the crystal to the exact frequency required to turn the platter at the selected speed. The DSP core will also generate a near perfect sinusoidal waveform to power the motor. Factory set vibration removal and fine speed adjustments are then made to the power supply to tune each motor for optimal performance.

Dust Cover

The outer frame of the previous model has now been removed and a new stylish, removable, single piece dustcover has been introduced further reducing the overall mass of the turntable.

- Mains voltage:

- 230 V 50/60 Hz

- 220 V 50/60Hz

- 115 V 50/60Hz

- 100 V 50/60Hz

- Power consumption: 17 W

- Fuse rating: T250 mA L (230 V / 220 V)T500 mA L (115 V / 100 V)

- Output to motor: 24 V AC bi-phase ~ 350 mA

- Speed control step size: 0.01 rpm

|

.jpg) Ultra-lightweight plinth

The Planar 10 is the third Rega turntable constructed using their latest technology the ultra-lightweight Tancast 8 polyurethane foam core (a material developed for the aerospace industry). This material is sandwiched between two layers of HPL (high-pressure laminate). HPL is exceptionally thin and extremely rigid. This new construction makes the new Planar 10 skeletal plinth 30% lighter than the original RP10 while offering increased rigidity over the previous model.

DB Technology (Double Brace Technology)

A super lightweight plinth combined with a ceramic top brace and phenolic resin bottom brace mounted specifically where the increased rigidity is required (between the tonearm mounting and the main hub bearing) forms a structurally sound, “stressed beam,” assembly. This rigid plinth design prevents energy absorption and unwanted resonances which will add unnatural distortions to the music. Equally, heavier mass can transfer more unwanted energy such as motor or bearing noise directly into the rotating record. The tonearm and cartridge must be able to read accurately, directly from the platter. This unique Rega double brace solution enables this. The use of braces instead of the complete skin allows increased thickness in these key areas while providing further weight reduction to the plinth which directly addresses the issue of mass absorption and unwanted energy transmission.

RB3000 tonearm

Rega is renowned for the quality of its tonearm bearing assemblies. In particular the accurate manufacturing of their bearing housing and bearing spindles. Technical characteristics such as "roundness" and "parallelity" are critical. Over the past three years, Rega has found a new manufacturing process that improves on all these characteristics resulting in a micron perfect bearing fit. The RB3000 is the first Rega arm to benefit from these improvements.

The entire tonearm structure is designed to have the minimum of mechanical joints while using the stiffest materials in all critical areas. The tolerance of the RB3000 tonearm is so tight that no adhesive is used at any point throughout the construction. Their latest low mass, precision-engineered, the vertical bearing assembly has been manufactured to further complement the inherent design philosophy of the Planar 10 turntable. The RB3000 tonearm uses Rega's advanced, preloaded zero tolerance bearing assembly adjusted to less than 1000th of a mm. This gives friction-free movement and zero levels of unwanted play. Simply put, friction-free bearings with no play enable ridges in the record groove of less than a micron to be read. The RB3000 also uses their latest award-winning, aluminum, Rega arm tube (each one of which is meticulously hand polished, keeping mass to an absolute minimum) which was redesigned to redistribute mass and further reduce stresses and resonances. This advanced design tube increases the stiffness and rigidity of the overall assembly whilst reducing stress on the bearings even further.

Hub Bearing assembly

The Planar 10 uses a new low mass central bearing assembly. A single piece of machined aluminum sub-platter and hardened tool steel spindle run inside a custom brass housing designed with improved mechanical integrity. The complete assembly is cleverly mounted within the chassis to eradicate unwanted potential energy being transferred or stored in the plinth.

Ultra-lightweight plinth

The Planar 10 is the third Rega turntable constructed using their latest technology the ultra-lightweight Tancast 8 polyurethane foam core (a material developed for the aerospace industry). This material is sandwiched between two layers of HPL (high-pressure laminate). HPL is exceptionally thin and extremely rigid. This new construction makes the new Planar 10 skeletal plinth 30% lighter than the original RP10 while offering increased rigidity over the previous model.

DB Technology (Double Brace Technology)

A super lightweight plinth combined with a ceramic top brace and phenolic resin bottom brace mounted specifically where the increased rigidity is required (between the tonearm mounting and the main hub bearing) forms a structurally sound, “stressed beam,” assembly. This rigid plinth design prevents energy absorption and unwanted resonances which will add unnatural distortions to the music. Equally, heavier mass can transfer more unwanted energy such as motor or bearing noise directly into the rotating record. The tonearm and cartridge must be able to read accurately, directly from the platter. This unique Rega double brace solution enables this. The use of braces instead of the complete skin allows increased thickness in these key areas while providing further weight reduction to the plinth which directly addresses the issue of mass absorption and unwanted energy transmission.

RB3000 tonearm

Rega is renowned for the quality of its tonearm bearing assemblies. In particular the accurate manufacturing of their bearing housing and bearing spindles. Technical characteristics such as "roundness" and "parallelity" are critical. Over the past three years, Rega has found a new manufacturing process that improves on all these characteristics resulting in a micron perfect bearing fit. The RB3000 is the first Rega arm to benefit from these improvements.

The entire tonearm structure is designed to have the minimum of mechanical joints while using the stiffest materials in all critical areas. The tolerance of the RB3000 tonearm is so tight that no adhesive is used at any point throughout the construction. Their latest low mass, precision-engineered, the vertical bearing assembly has been manufactured to further complement the inherent design philosophy of the Planar 10 turntable. The RB3000 tonearm uses Rega's advanced, preloaded zero tolerance bearing assembly adjusted to less than 1000th of a mm. This gives friction-free movement and zero levels of unwanted play. Simply put, friction-free bearings with no play enable ridges in the record groove of less than a micron to be read. The RB3000 also uses their latest award-winning, aluminum, Rega arm tube (each one of which is meticulously hand polished, keeping mass to an absolute minimum) which was redesigned to redistribute mass and further reduce stresses and resonances. This advanced design tube increases the stiffness and rigidity of the overall assembly whilst reducing stress on the bearings even further.

Hub Bearing assembly

The Planar 10 uses a new low mass central bearing assembly. A single piece of machined aluminum sub-platter and hardened tool steel spindle run inside a custom brass housing designed with improved mechanical integrity. The complete assembly is cleverly mounted within the chassis to eradicate unwanted potential energy being transferred or stored in the plinth.

Cutaway cross-section of Planar 10 bearing assembly.

Ceramic Platter

The P10 uses a custom ceramic, flywheel effect platter. The platter is produced from ceramic oxide powder which is compressed, fired and diamond cut to ensure perfect accuracy and flatness across the surface. The latest platter features a modified construction with improved coupling to the sub-platter.

24v Low noise motor assembly

The Planar 10 uses Rega's latest generation, 24v, synchronous, low vibration motor technology. Uniquely mounted using the highest level of coupling while retaining higher vibration isolation than any previous model, this new motor mounting technique (mounted from the bottom) has been taken directly from the ultimate Rega turntable, the Naiad. This unique mounting method removes all stress from the motor body whilst holding the drive pulley perfectly still. This enables better speed stability and accuracy from the turntable. The reduced vibration and more rigid mounting delivers superior drive from the new EBLT drive belts. Each motor is hand-tuned to match its own custom-matched PL10 PSU power supply before fitting to the turntable to optimize the anti-vibration circuit.

EBLT Drive Belts

For three years Rega has been researching and developing with chemists the use of a bespoke new rubber compound for drive belts. Using a specialized curing system, the new drive belt offers superior consistency of modulus (a constant representing the degree to which a substance has a particular property, especially elasticity). These new belts are manufactured on Rega designed, state of the art, super-accurate tools (inspired by working with the manufacturer of high-tech Formula 1 engine parts) which produce 'perfectly round' and 'dimensionally accurate' belts, critical for perfect speed stability.

PL10 PSU custom-matched advanced power supply.

The PL10 PSU offers the ultimate in motor control stability, convenient electronic speed change, advanced anti-vibration control, and user-adjustable electronic fine speed adjustment to ensure total accuracy and control over the life of the motor. Housed in Rega's latest custom-designed case, the PL10 PSU is dedicated to running our 24v, low noise motor as quietly and as accurately as possible. The speed and control of the motor is achieved by using a new DSP (Digital Signal Processing) generator built upon a high stability crystal. This device will divide the accurate square wave from the crystal to the exact frequency required to turn the platter at the selected speed. The DSP core will also generate a near perfect sinusoidal waveform to power the motor. Factory set vibration removal and fine speed adjustments are then made to the power supply to tune each motor for optimal performance.

Dust Cover

The outer frame of the previous model has now been removed and a new stylish, removable, single piece dustcover has been introduced further reducing the overall mass of the turntable.

Cutaway cross-section of Planar 10 bearing assembly.

Ceramic Platter

The P10 uses a custom ceramic, flywheel effect platter. The platter is produced from ceramic oxide powder which is compressed, fired and diamond cut to ensure perfect accuracy and flatness across the surface. The latest platter features a modified construction with improved coupling to the sub-platter.

24v Low noise motor assembly

The Planar 10 uses Rega's latest generation, 24v, synchronous, low vibration motor technology. Uniquely mounted using the highest level of coupling while retaining higher vibration isolation than any previous model, this new motor mounting technique (mounted from the bottom) has been taken directly from the ultimate Rega turntable, the Naiad. This unique mounting method removes all stress from the motor body whilst holding the drive pulley perfectly still. This enables better speed stability and accuracy from the turntable. The reduced vibration and more rigid mounting delivers superior drive from the new EBLT drive belts. Each motor is hand-tuned to match its own custom-matched PL10 PSU power supply before fitting to the turntable to optimize the anti-vibration circuit.

EBLT Drive Belts

For three years Rega has been researching and developing with chemists the use of a bespoke new rubber compound for drive belts. Using a specialized curing system, the new drive belt offers superior consistency of modulus (a constant representing the degree to which a substance has a particular property, especially elasticity). These new belts are manufactured on Rega designed, state of the art, super-accurate tools (inspired by working with the manufacturer of high-tech Formula 1 engine parts) which produce 'perfectly round' and 'dimensionally accurate' belts, critical for perfect speed stability.

PL10 PSU custom-matched advanced power supply.

The PL10 PSU offers the ultimate in motor control stability, convenient electronic speed change, advanced anti-vibration control, and user-adjustable electronic fine speed adjustment to ensure total accuracy and control over the life of the motor. Housed in Rega's latest custom-designed case, the PL10 PSU is dedicated to running our 24v, low noise motor as quietly and as accurately as possible. The speed and control of the motor is achieved by using a new DSP (Digital Signal Processing) generator built upon a high stability crystal. This device will divide the accurate square wave from the crystal to the exact frequency required to turn the platter at the selected speed. The DSP core will also generate a near perfect sinusoidal waveform to power the motor. Factory set vibration removal and fine speed adjustments are then made to the power supply to tune each motor for optimal performance.

Dust Cover

The outer frame of the previous model has now been removed and a new stylish, removable, single piece dustcover has been introduced further reducing the overall mass of the turntable.

Reviews

There are no reviews yet.